Rittal – From saving electricity to the energy transition

The “All Electric Society” is making huge strides, leading to significant changes in the power grids and the entire energy system.

Will industry have enough affordable electricity available? This is a decisive question for the future of companies and the business location. At the SPS trade fair, Rittal, Eplan, Cideon and German Edge Cloud will show how the industry can become an enabler in several critical areas through combined competencies, standardised processes and connected data spaces – from power generation and storage to sector coupling and power distribution to the management of energy flows in their businesses and factories.

Industrialising entire process chains with consistent data and coordinated software and hardware as a overarching principle of action for establishing the energy transition infrastructure.

The affiliated companies will be talking with trade fair visitors about which concrete opportunities the transformation can create for panel builders and switchgear manufacturers, as well as for the energy industry and factory operators.

“The overarching principle of action is to industrialise entire process chains with consistent data and coordinated software and hardware,” says Raphael Görner, Head of Rittal’s Energy & Power Solutions Business Unit.

This is reflected, for example, in energy grids. Regardless of a scarcity of skilled workers, speed is required when building new infrastructure. Rittal and Eplan will discuss the role of digital twins in the “Energy Flash online talk”.

“We need high data quality right from the start so that the digital workflow can unfold its full effect,” says Jan Oliver Kammesheidt, Vertical Market Manager Energy at Eplan: “Our experience with the high degree of industrialisation in mechanical engineering shows this potential. We want to make these systemic benefits, including automated engineering, even more accessible to the energy sector.“

Pioneering solutions for network infrastructure

Visitors to the trade fair will see concrete implementation based on the example of a transformer station. Grid operators need large numbers of transformer and substations to distribute electricity to end consumers efficiently. The idea is that Eplan offers a complete standard-compliant industrial project as a default, including a list of equipment typical for the industry. It only needs to be customised if required. This creates more speed through standardisation, starting as early as the engineering stage.

The data record also contains all the information needed for modular Rittal system technology and for processing with machines from Rittal Automation Systems and Ehrt in further processes. The result: greatly reduced time and costs, standard-compliant execution and a digital twin for operations.

“With Eplan and Rittal as pacemakers, we are expanding this standardisation principle for ever more applications,” Mr. Görner explains.

Energy efficiency transition for industry

However, not only do the grids and energy systems need to be expanded to achieve the energy transition. Manufacturing industry companies must also initiate an energy efficiency transition. These consume almost 45% of Germany’s electricity. This will call for high consistency in using energy-saving technologies and, secondly, the reorganisation of manufacturing processes as smart production so that they can be managed according to energy aspects.

“When it comes to infrastructure, we want to support our customers, particularly in the area of climate control for enclosures, machines, IT solutions and energy storage systems so that we can tap into the major potentials for optimisation,” says Lars Platzhoff, Head of Rittal’s Cooling Solutions Business Unit: “Market-leading energy-saving cooling technology is the foundation, but we must also simplify planning, configuration, replacement and operation for our customers to broaden the range of technologies.”

As a result, Rittal focuses on expanding Rittal Blue e+ cooling technology with energy savings of up to 75% for ever more applications and offers customers comprehensive advice and services like efficiency analyses and ROI calculations.

Seemingly simple technology made smart: The new Blue e+ fan-and-filter units transmit data via the Rittal IoT interface and issue temperature alarms and filter replacement predictions.

The latest trade fair innovation is the RiTherm application. The tool, which has now been set up in the Eplan Cloud, supports customers in planning the climate control of control and switchgear systems, including the heat dissipation certificate and carbon footprint. Rittal is now making even seemingly simple technology intelligent: The new Blue e+ fan-and-filter units supply data via the Rittal IoT interface and issue temperature alarms.

“We also see a great potential for development in IT cooling. Given the increasing power density in data centres, direct liquid cooling will play an increasingly important role, in part because it makes heat recovery easier,” Mr. Platzhoff adds.

From saving energy to management via smart production

In factories, the transformation must cover more than just the pure energy efficiency of the systems.

“If we no longer have enough cheap electricity available all the time, factory operators will have to manage their production according to the availability and price of energy,” explains Dieter Meuser, CEO of Digital Solutions at German Edge Cloud: “The basis for this is the flexibility of a universal digital platform such as the ONCITE Digital Production System, which integrates energy monitoring data into the transparency of smart production.”

To do so, it must be linked to the data rooms relating to products and automation. This is where the sister companies contribute their expertise: Eplan and Rittal for the automation twin and Cideon for the product twin.

In the future, factory operators will also have to manage their production based on the availability and price of energy. The basis will be a universal digital platform, such as the ONCITE Digital Production System for the transparency of smart production.

SourceRittal

EMR Analysis

More information on The Friedhelm Loh Group: See the full profile on EMR Executive Services

More information on Prof. Friedhelm Loh (Owner and Chief Executive Officer, The Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on Rittal: See the full profile on EMR Executive Services

More information on Markus Asch (Chief Executive Officer, Rittal International and Rittal Software Systems + Chairman of the Management Board, the Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on Raphael Görner (Executive Vice President, Global Energy & Power Solutions Business Unit, Rittal, the Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on Dipl. Ing. Lars Platzhoff (Executive Vice President, Cooling Solutions Business Unit, Rittal, the Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on Blue e+ Cooling Unit Series by Rittal: https://www.rittal.com/de_de/blue_e/plus_preview/public/en + Energy Efficiency through hybrid technology.

Hybrid technology: Ploneering climate control with Energy Efficiency up to 75%

- Average energy savings of 75%

- Active cooling circuit with speed-regulated components for demand-based cooling

- Integral heat pipe for passive cooling

- Constant temperature inside the enclosure

- Component-friendly cooling for a longer service life

More information on RiTherm by Rittal: https://www.rittal.com/ie-en/content/en/support/software/projektieren/therm/Therm.jsp + Calculation program for the climate control of enclosures

The Therm software package takes care of the complex calculation of climate control requirements. A user-friendly interface guides you to the most suitable, correctly dimensioned climate control component. At the end of the calculation, you receive detailed documentation that you can either print out or simply transfer into your preferred word processing program. This provides maximum peace of mind when calculating climate control components.

More information on Eplan: See the full profile on EMR Executive Services

More information on Jan Oliver Kammesheidt (Global Vertical Market Manager, Energy, Eplan, the Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on Cideon: See the full profile on EMR Executive Services

More information on German Edge Cloud (GEC): See the full profile on EMR Executive Services

More information on Dieter Meuser (Chief Executive Officer, Digital Solutions, German Edge Cloud, the Friedhelm Loh Group): See the full profile on EMR Executive Services

More information on ONCITE Industrial Software Suite by German Edge Cloud (GEC): https://gec.io/en/industrial-solutions/oncite-digital-production-system/oncite-industrial-suite/ + Powerful cloud-native software applications for the factory

Today’s factory adapts quickly to new circumstances. With the cloud-native software applications of the ONCITE Industrial Suite, which are orchestrated using plug & produce on the ONCITE Factory Edge, you build the functional basis for a digital, variant-rich, agile and adaptable production. The solutions help you achieve more flexibility, transparency and efficiency in your production.

Take shop floor process management and automation to a new level. Data collection and management allow you to exploit optimisation potential that was not visible before. Machines become more efficient, machine status can be monitored more comprehensively, and unplanned downtimes are avoided. Use the possibilities of the online validation of production and process data to significantly increase your product quality.

More information on SPS 2023 (Smart Production Solutions) Germany (14-16 November 2023, Nüremberg, Germany): https://sps.mesago.com/nuernberg/en.html + Bringing Automation to Life.

The SPS is the industry highlight of the automation sector and, with its unique concept, represents the complete spectrum of smart and digital automation – from simple sensors to intelligent solutions, from what is feasible today to the vision of a comprehensively digitized industrial world.

More information on Federal Ministry of Economic Affairs and Climate Action (BMWK), Germany: https://www.bmwk.de/Navigation/EN/Home/home.html

More information on GNDEW (Draft law to restart the digitization of the energy transition in Germany): https://www.bmwk.de/Redaktion/DE/Artikel/Service/Gesetzesvorhaben/neustart-der-digitalisierung-der-energiewende.html

EMR Additional Notes:

- Grid, Microgrids and DERs:

- The power grid is a network for delivering electricity to consumers. The power grid includes generator stations, transmission lines and towers, and individual consumer distribution lines.

- The grid constantly balances the supply and demand for the energy that powers everything from industry to household appliances.

- Electric grids perform three major functions: power generation, transmission, and distribution.

- A microgrid is a small-scale power grid that can operate independently or collaboratively with other small power grids. The practice of using microgrids is known as distributed, dispersed, decentralized, district or embedded energy production.

- Smart Grid is any electrical grid + IT at all levels . Micro Grid is a group of interconnected loads and DERs (Distributed energy resources) within a clearly defined electrical and geographical boundaries witch acts as a single controllable entity with respect to the main grid.

- Distributed Energy Resources (DERs) are small-scale electricity supply (typically in the range of 3 kW to 50 MW) or demand resources that are interconnected to the electric grid. They are power generation resources and are usually located close to load centers, and can be used individually or in aggregate to provide value to the grid.

- Common examples of DERs include rooftop solar PV units, natural gas turbines, microturbines, wind turbines, biomass generators, fuel cells, tri-generation units, battery storage, electric vehicles (EV) and EV chargers, and demand response applications.

- Distributed Energy Resources Management systems (DERMS) are platforms which helps mostly distribution system operators (DSO) manage their grids that are mainly based on Distributed Energy Resources (DER).

- DERMS are used by utilities and other energy companies to aggregate a large energy load for participation in the demand response market. DERMS can be defined in many ways, depending on the use case and underlying energy asset.

- Software vs. Hardware vs. Firmware:

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Since hardware is part of the “real” world, it all eventually wears out. Being a physical thing, it’s also possible to break it, drown it, overheat it, and otherwise expose it to the elements.

- Here are some examples of hardware:

- Smartphone

- Tablet

- Laptop

- Desktop computer

- Printer

- Flash drive

- Router

- Software is virtual: It can be copied, changed, and destroyed.

- Software is everything about your computer that isn’t hardware.

- Here are some examples of software:

- Operating systems like Windows 11 or iOS

- Web browsers

- Antivirus tools

- Adobe Photoshop

- Mobile apps

- Firmware is virtual: It’s software specifically designed for a piece of hardware

- While not as common a term as hardware or software, firmware is everywhere—on your smartphone, your PC’s motherboard, your camera, your headphones, and even your TV remote control.

- Firmware is just a special kind of software that serves a very narrow purpose for a piece of hardware. While you might install and uninstall software on your computer or smartphone on a regular basis, you might only rarely, if ever, update the firmware on a device, and you’d probably only do so if asked by the manufacturer, probably to fix a problem.

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Return on Investment (ROI):

- Return on Investment (ROI) is a popular profitability metric used to evaluate how well an investment has performed. ROI is expressed as a percentage and is calculated by dividing an investment’s net profit (or loss) by its initial cost or outlay.

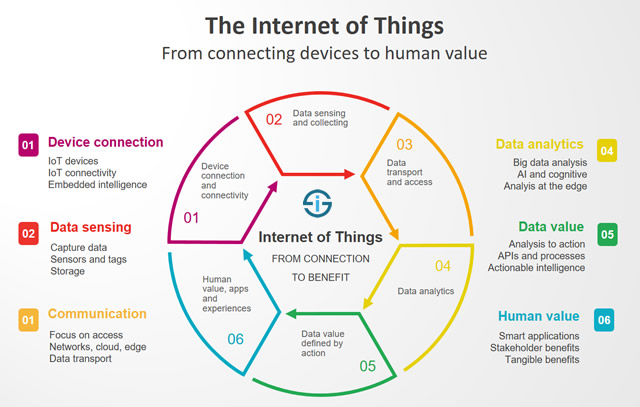

- IOT (Internet Of Things):

- The Internet of Things (IoT) refers to a system of interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

- Describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

- The Most Popular IoT Devices are:

- Smart watches are the most popular IoT devices. …

- Gaming consoles. …

- Smart TV sets and content streaming devices. …

- Voice control devices. …

- Printers. …

- Cameras. …

- Lighting appliances. …

- Smart thermostats.

- IIoT (Industrial IoT):

- Industrial IoT (IIoT) involves collecting and analyzing sensor-generated data to support equipment monitoring and maintenance, production process analytics and control, and more. In manufacturing IT since 1989, ScienceSoft offers IIoT consulting and development to create secure IIoT solutions.

- xIoT (xTended Internet of Things):

- xIoT refers to the “xTended” Internet of Things. This xTended IoT category spans Enterprise IoT devices (cameras, printers, and door controllers), OT devices (like PLCs, HMI’s, and robotics) and Network devices (like switches, WiFi routers, and NAS).

- Switchgears:

- Broad term that describes a wide variety of switching devices that all fulfill a common need: controlling, protecting, and isolating power systems. This definition can be extended to include devices to regulate and meter a power system, circuit breakers, and similar technology.

- Switchgear contains fuses, switches, and other power conductors. However, circuit breakers are the most common component found in switchgear.

- Performs the function of controlling and metering the flow of electrical power in addiction to acting as interrupting and switching devices that protects the equipment from damage arising out of electrical fluctuations.

- There are three types of switch gears namely LV (Low voltage), MV (Medium voltage) and HV (High voltage) Switchgear.

- Circuit Breakers:

- Mechanical electrical switch designed to protect an electrical circuit from damage caused by overcurrent/overload or short circuit. Its basic function is to interrupt current flow after protective relays detect a fault.

- By definition a circuit breaker is an electrical safety device, a switch that automatically interrupts the current of an overloaded electric circuit, ground faults, or short circuits.

- Fuses:

- Single time mechanical circuit interruption in an over-current situation through fusion of a graded electrical conductor. Employed in 30KV to 100KV range.

- Electrical safety device that operates to provide overcurrent protection of an electrical circuit. Its essential component is a metal wire or strip that melts when too much current flows through it, thereby stopping or interrupting the current.

- ACB (Air Circuit Breakers):

- Uses air as insulating medium.

- Air circuit breaker is a circuit breaker for the purpose of protecting low voltage circuit, mainly for energizing and cutting off high current

- VCB (Vacuum Circuit Breakers):

- Vacuum is used as the means to protect circuit breakers.

- Circuit breaker where the arc quenching takes place in a vacuum medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called a vacuum interrupter.

- AIS (Air Insulated Switchgears):

- Air is used for insulation in a metal-clad system

- Secondary power distribution device and medium voltage switchgear that helps redistribute the power of a primary power distributor powered by a high voltage distribution transformer. AIS controls, protects and isolates electrical equipment in power transmission and distribution systems.

- GIS (Gas Insulated Switchgears):

- All working components assembled under SF6 (Sulfur Hexafluoride HV Switchgears) gas-tight casing.

- Compact metal encapsulated switchgear consisting of high-voltage components such as circuit-breakers and disconnectors, which can be safely operated in confined spaces.

- OCB (Oil Circuit Breakers):

- Vapors a portion of oil to blast a jet of oil through the arc.

- Circuit breaker which uses insulating oil as an arc quenching medium

- Hybrid Circuit Breakers:

- Combines Air-insulated and SF6 Gas-insulated technologies.

- MCB (Miniature Circuit Breakers):

- Employed in domestic households to safeguard against overload. Rated current max. 100 A.

- Electrical switch that automatically switches off the electrical circuit during an abnormal condition of the network means an overload condition as well as a faulty condition. Nowadays we use an MCB in a low-voltage electrical network instead of a fuse.

- Circuit breakers have a tripping relay mechanism, while MCB has a tripping release mechanism. Circuit breakers have a high rupturing capacity, but the MCB has a low rupturing capacity. Circuit breakers are used in High Voltage systems, while MCBs are used in Low Voltage systems.

- RCCB (Residual Current Circuit Breakers):

- To safeguard against electrical shock arising out of indirect contact and includes the detection of residual current such as earth leakage.

- Current sensing device, which can automatically measure and disconnect the circuit whenever a fault occurs in the connected circuit or the current exceeds the rated sensitivity.

- MCCB (Molded Case Circuit Breakers):

- Incorporates insulating material in the form of molded casing within circuit breaker. Rated current up to 2,500 A.

- MCCB has a higher interrupting capacity, meaning it can handle larger loads than a conventional breaker. Generally, a standard breaker is used for residential and light commercial applications, while an MCCB is suitable for industrial and heavy commercial applications.

- Disconnectors:

- Automatic switching device that offers specific isolating distance on the basis of specific requirements.

- Disconnectors (also known as Isolators) are devices which are generally operated off-load to provide isolation of main plant items for maintenance, or to isolate faulted equipment from other live equipment.

- Contactors:

- Works alike high-current switching systems but at higher voltage rates. Contactors can however not be utilized as disconnecting switches. Contactors are employed in 30KV to 100KV range.

- Special type of relay used for switching an electrical circuit on or off.

- Electrical device that is widely used for switching circuits on and off. As such, electrical contactors form a subcategory of electromagnetic switches known as relays. A relay is an electrically operated switching device that uses an electromagnetic coil to open and close a set of contacts.

- PTCB eFuse Circuit Breaker:

- Electronic micro fuse for DIN rail protecting electronically nominal currents below 1A to facilitate the clear detection of faults and supports precise fault localization and fast recovery. Response times are shorter compared to conventional fuse protection and the exact current value can be adjusted at any time

- RCD (Residual Current Devices):

- Sensitive safety device that switches off the electricity within 10 to 50 milliseconds if there is an electrical fault. An RCD is is designed to protect against the risks of electrocution and fire caused by earth faults.

- The difference between a circuit breaker and an RCD switch is the purpose of a circuit breaker is to protect the electrical systems and wiring in a home while the purpose of an RCD switch is to protect people from electrocution.

- RCBO (Residual Current Breaker with Over-Current):

- RCDs can protect against electric shocks, residual currents, and earth faults. On the other hand, RCBOs can do what RCDs can do and protect a circuit from short circuits and overload. RCBOs are essentially a combination of MCB and RCCB.

- An RCBO protects electrical equipment from two types of faults; residual current and over current. Residual current, or Earth leakage as it can sometimes be referred to, is when there is a break in the circuit that could be caused by faulty electrical wiring or if the wire is accidentally cut.

- Ring Main Unit (RMU):

- Medium voltage, gas-insulated, fully sealed cabinet used to measure, connect, and integrate transformer protection functions with a fixed type breaker. Ring Main Units are safe, reliable, low-maintenance, and easy to replace switchgear.

- A ring main unit (RMU) is a factory assembled, metal enclosed set of switchgear used at the load connection points of a ring-type distribution network.

- Load Center – Panel Board – Switch Board:

- A load center is used in residential and light commercial applications to distribute electricity supplied by the utility company throughout the home or building to feed all the branch circuits. Each branch circuit is protected by the circuit breaker housed in the load center. In the event of a short circuit or an overload on a branch circuit, the circuit breaker will cut the power before any potential property damage or personal injury can occur.

- A load center provides similar functionality in a power distribution system as a switchboard and a panelboard. As far as UL and the NEC standards are concerned, there is no difference between a panelboard and a load center.

- However, Panelboards are typically deeper than load centers and can accommodate both bolt-on circuit breakers as well as plug-in breakers, whereas a load center is limited to plug-in breakers.

- Switchboards are often the typical choice for industrial establishments. These panelboards generally house circuit breakers that can manage and supply electricity for machines with high-voltage demands.

- Panelboards are only accessible from the front (as mentioned above), but switchboards allow rear access as well.

- Carbon Dioxide (CO2):

- Primary greenhouse gas emitted through human activities. Carbon dioxide enters the atmosphere through burning fossil fuels (coal, natural gas, and oil), solid waste, trees and other biological materials, and also as a result of certain chemical reactions (e.g., manufacture of cement). Carbon dioxide is removed from the atmosphere (or “sequestered”) when it is absorbed by plants as part of the biological carbon cycle.

- Biogenic Carbon Dioxide (CO2):

- Carbon Dioxide released as a result of the combustion or decomposition of organic material, that is biomass and its derivatives. Examples include carbon dioxide released during the combustion of wood and biogas generated by decomposition.

- Biogenic Carbon Dioxide (CO2) and Carbon Dioxide (CO2) are the same. Scientists differentiate between biogenic carbon (that which is absorbed, stored and emitted by organic matter like soil, trees, plants and grasses) and non-biogenic carbon (that found in all other sources, most notably in fossil fuels like oil, coal and gas).

- Carbon Capture and Storage (CCS):

- CCS involves the capture of carbon dioxide (CO2) emissions from industrial processes, such as steel and cement production, or from the burning of fossil fuels in power generation. This carbon is then transported from where it was produced, via ship or in a pipeline, and stored deep underground in geological formations.

- CCS projects typically target 90 percent efficiency, meaning that 90 percent of the carbon dioxide from the power plant will be captured and stored.

- Decarbonization:

- Reduction of carbon dioxide emissions through the use of low carbon power sources, achieving a lower output of greenhouse gasses into the atmosphere.

- Carbon Footprint:

- There is no universally agreed definition of what a carbon footprint is. A carbon footprint is generally understood to be the total amount of greenhouse gas (GHG) emissions that are directly or indirectly caused by an individual, organization, product, or service. These emissions are typically measured in tonnes of carbon dioxide equivalent (CO2e).

- In 2009, the Greenhouse Gas Protocol (GHG Protocol) published a standard for calculating and reporting corporate carbon footprints. This standard is widely accepted by businesses and other organizations around the world. The GHG Protocol defines a carbon footprint as “the total set of greenhouse gas emissions caused by an organization, directly and indirectly, through its own operations and the value chain.”

- Digital Twin:

- Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimize through real time analytics to deliver business value.

- A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.