Siemens – Siemens expands its additive manufacturing offerings on the Siemens Xcelerator Marketplace

- Siemens Xcelerator enables the scaling of additive manufacturing solutions: achieving goals faster and more successfully with partners

- Additive manufacturing with Siemens technology accelerates the path to a circular economy

- AM I Navigator: Initiative expands to include Stratasys

Under the motto “Let’s advance Manufacturing,” Siemens and selected partners will demonstrate at Formnext 2024 how additive manufacturing (AM) is becoming an innovation enabler for industrial applications thanks to a functioning ecosystem, digitalization, and automation. Additive manufacturing has become an established production technology in which productivity, costs, quality, and availability are critical to long-term market viability. The Siemens Xcelerator strategy emphasizes the importance of innovation and technology partnerships as well as open, interoperable technologies. They are essential when it comes to facilitating the integration of AM into conventional manufacturing technologies, meeting standardized quality and safety requirements, and accelerating the scaling of AM solutions. As a result, Siemens brings additive manufacturing offerings from additional partners in the Siemens Xcelerator Marketplace.

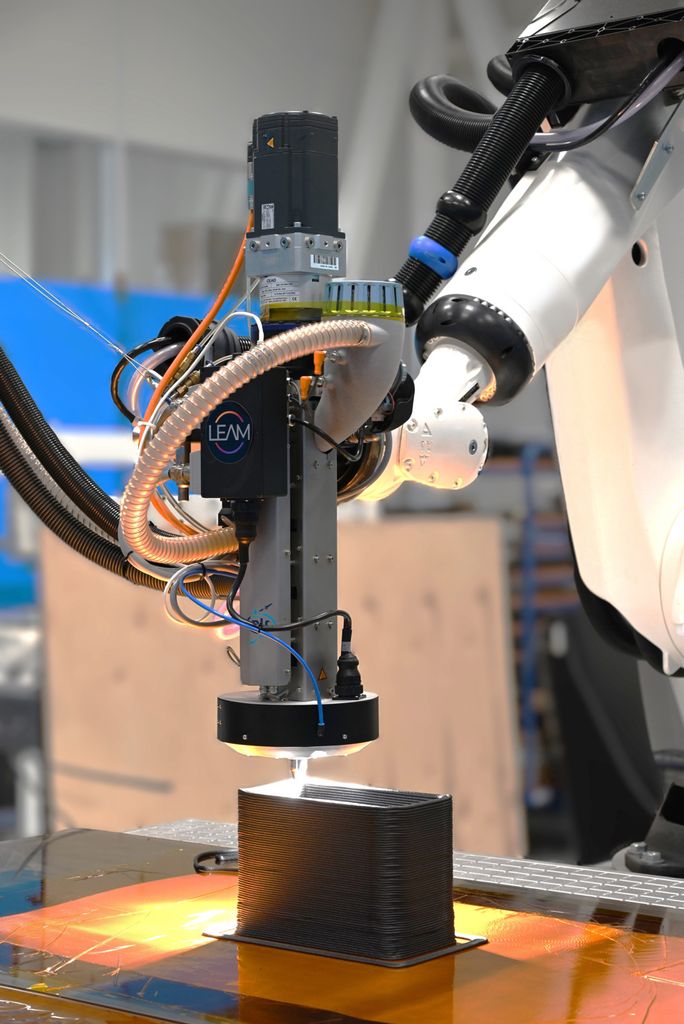

LEAM Technologies is revolutionizing large format additive manufacturing (LFAM) with light-based welding technology.

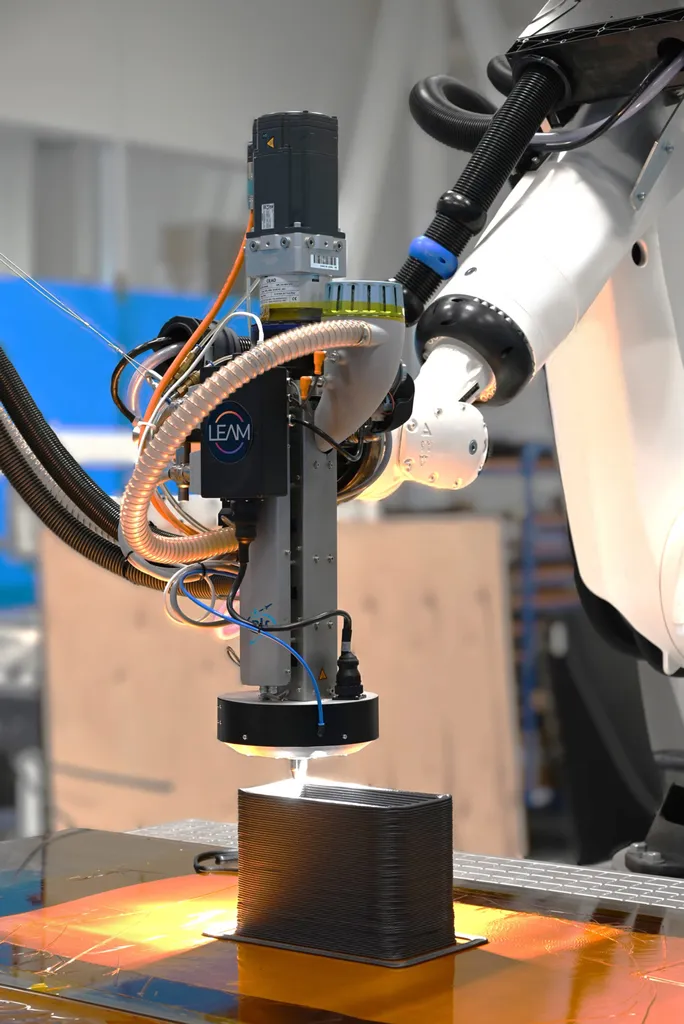

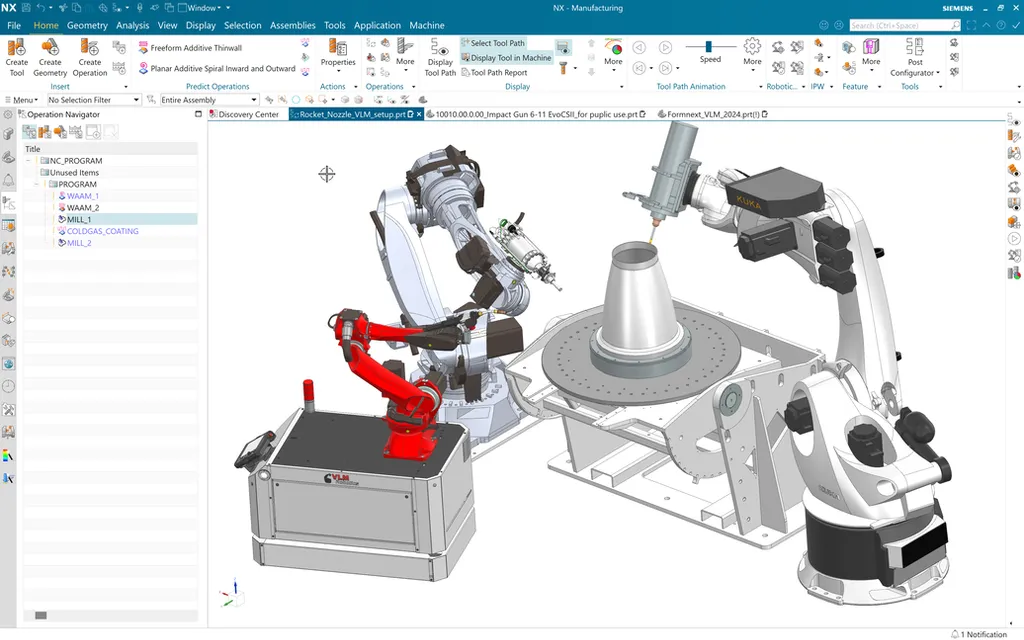

VLM Robotics, builder of XXL manufacturing machines, offers innovative and turnkey solutions for the railway, shipbuilding, aerospace, and energy industries. At Formnext, VLM Robotics will debut its new model CALYPSO, a fully automated autonomous mobile robotic solution based on Sinumerik One, Sinumerik CNC Robotics, and Simove for the first time, in addition to its well-known CNC robotic machines. Its GEMINI machine for XXL hybrid additive manufacturing will also be on display at the booth. VLM Robotics hybrid robotic solutions can perform printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM Robotics’ range of CNC robotic machines can be seamlessly integrated into the production environment, enabling agile repair and production work on large components. Digital threads play a vital role in this, as they are end-to-end digital twins of all data and information across the entire lifecycle of a product, machine, and process, enabling seamless integration and transparency from development to disposal. The complexity of controlling a highly scalable multi-technology robotic machine while meeting high precision and quality requirements requires a high level of industry, automation, and digitalization expertise. VLM Robotics is now represented on the Siemens Xcelerator Marketplace, where it offers customized digital solutions that enable the seamless integration and tracking of all relevant data and information throughout the entire production lifecycle.

At Formnext, VLM Robotics presents a fully automated autonomous mobile robot solution based on Sinumerik One, Sinumerik CNC Robotics and Simove.

Additive manufacturing with Siemens technology paves the way to a circular economy

Additive manufacturing is also an important enabler of the circular economy. Designing products so that they can be reused, recycled, or safely returned to the environment at the end of their lifecycle promotes a sustainable value chain, reduces waste, and conserves resources. Product design plays a vital role in this since 80 percent of the environmental impact is determined in the design phase. Siemens relies on industrial AI and the industrial metaverse to generate optimized designs and enable automated, intelligent workflows. Thanks to Siemens solutions, Toolcraft, for instance, can improve the design and engineering process for components by 30 percent for new designs and 85 percent for design modifications.

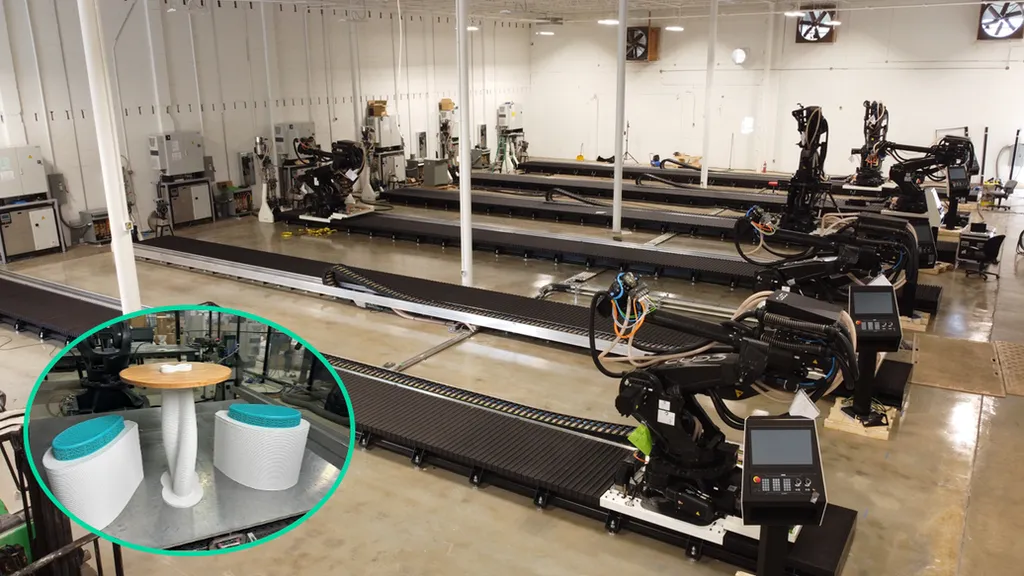

Haddy is revolutionizing furniture manufacturing with advanced 3D printing and robotics, producing high-quality, sustainable products at a low cost and on a commercial scale. Haddy is building a global network of local microfactories equipped with hybrid Flexbot systems from CEAD and recycling units that shorten the supply chain and help the environment by reducing waste. By collecting detailed data during the manufacturing process, the company is able to continuously optimize its robots for greater speed, accuracy, and efficiency. Committed to environmental responsibility, Haddy uses only renewable, recyclable materials. It also introduces a truly circular system for its products through Haddy Inside RFID chips and a scalable cloud API solution, allowing for responsible material tracing and recycling, enabling sustainable production and significantly reducing its environmental footprint.

Haddy is building a global network of local microfactories equipped with hybrid Flexbot systems and recycling units that shorten the supply chain and help the environment by reducing waste.

AM I Navigator expands to include Stratasys

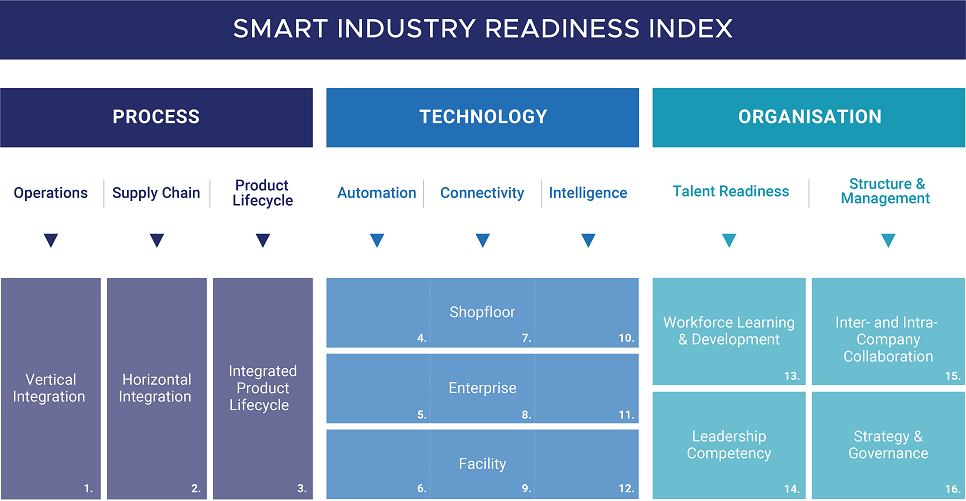

With Stratasys as a further partner, the AM I Navigator is entering the next round. Since the launch of the initiative in November 2023, the framework has been continuously refined and updated with concrete application examples. With its framework, the AM I Navigator provides a structured approach to defining the current status and the steps toward the target state of industrialized additive manufacturing. It builds on established frameworks for digital manufacturing, such as the Smart Industry Readiness Index (SIRI), which helps companies to assess their current level of digitalization and readiness for Industry 4.0 and to develop strategies for the modernization of their production processes.

SourceSiemens

EMR Analysis

More information on Siemens: See full profile on EMR Executive Services

More information on Dr. Roland Busch (President and Chief Executive Officer, Siemens AG): See full profile on EMR Executive Services

More information on Siemens Digital Industries (DI): See full profile on EMR Executive Services + https://new.siemens.com/global/en/company/about/businesses/digital-industries.html + Siemens Digital Industries (DI) empowers companies of all sizes within the process and discrete manufacturing industries to accelerate their digital and sustainability transformation across the entire value chain. Siemens’ cutting-edge automation and software portfolio revolutionizes the design, realization and optimization of products and production. And with Siemens Xcelerator – the open digital business platform – this process is made even easier, faster, and scalable. Together with our partners and ecosystem, Siemens Digital Industries enables customers to become a sustainable Digital Enterprise. Siemens Digital Industries has a workforce of around 70,000 people worldwide.

More information on Cedrik Neike (Member of the Managing Board and Chief Executive Officer, Siemens Digital Industries (DI), Siemens AG): See full profile on EMR Executive Services

More information on Xcelerator by Siemens: https://www.sw.siemens.com/en-US/digital-transformation/ + Xcelerator provides the engineering and manufacturing software, services and application development platform to blur the boundaries between industry domains. Companies can use this technology today to build the products of tomorrow. Turn complexity into your competitive advantage with Xcelerator.

Siemens Xcelerator consists of three pillars:

- Portfolio: A curated, modular portfolio of IOT-enabled hardware and software based on standard application programming interfaces, facilitating the integration of information technology (IT) and operational technology (OT).

- Ecosystem: A growing ecosystem of partners.

- Marketplace: Interactions and transactions among customers, partners and developers.

More information on Xcelerator Marketplace by Siemens: https://marketplace.siemens.com/global/en.html + Siemens Xcelerator is an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale. Access a curated portfolio of connected hardware and software, a powerful ecosystem of partners, and an extensive marketplace.

More information on AM I Navigator initiative by Siemens, DyeMansion, HP, BASF Forward AM, EOS and Stratasys: https://press.siemens.com/global/en/pressrelease/siemens-dyemansion-hp-basf-forward-am-and-eos-navigate-am-users-through-complex + Its holistic maturity model is shapeing the stages of industrialization in the AM industry, increasing interoperability in additive manufacturing. The model defines the stages of industrial 3D printing along the entire process chain from material to machines to automation. Moreover, creating a common understanding of the different stages helps AM users find ways to scale and integrate additive manufacturing into traditional production workflows.

With its framework, the AM I Navigator provides a structured approach to defining the current status and the steps toward the target state of industrialized additive manufacturing. It builds on established frameworks for digital manufacturing, such as the Smart Industry Readiness Index (SIRI), which helps companies to assess their current level of digitalization and readiness for Industry 4.0 and to develop strategies for the modernization of their production processes.

More information on Sinumerik One by Siemens: https://www.siemens.com/global/en/products/automation/systems/cnc-sinumerik/automation-systems/sinumerik-one.html + SINUMERIK ONE, the digital native CNC, brings your ideas to life. SINUMERIK ONE is the leading-edge CNC system for highly productive machine tools. For unprecedented new opportunities, ideas and business models. For faster innovation based on the seamless interaction of the virtual and real worlds. What’s more, SINUMERIK ONE represents much more than just a powerful hardware innovation.

More information on Sinumerik CNC Robotics by Siemens: https://www.siemens.com/us/en/products/automation/systems/sinumerik-cnc/technologies/robotics.html + Integrates CNC-controlled robots into machine tools to enhance manufacturing flexibility and productivity. These robotics applications enable seamless transition and compatibility between machine tools and robotic functions, making it possible to use robots for tasks like material handling, complex machining, or precision finishing. The system leverages the SINUMERIK platform, which combines CNC expertise with advanced automation technologies, ensuring a smooth integration without the need for specialized robotic programming knowledge.

More information on Simove by Siemens: https://xcelerator.siemens.com/global/en/industries/automotive-manufacturing/simove.html + Flexible production belongs to the future.

Increasing individualization, fast changes of production lines and volumes as well as highly automated processes – these key trends shaping the future of production and logistical processes. SIMOVE is our answer to these challenges and helps you to take the next step into future.

SIMOVE allows you to change your manufacturing lines into a flexible and modular production. Besides that it supports you in many areas of your enterprise processes from the moment of incoming material through the different production steps up to the dispatch of your goods. SIMOVE is based on standard Siemens automation and drives components and a modular software platform.

More information on Formnext 2024 (19 November to 22 November 2023 – Frankfurt, Germany): https://formnext.mesago.com/frankfurt/en.html + As the leading industry platform for Additive Manufacturing and industrial 3D Printing, Formnext is the international meeting point for the next generation of intelligent industrial production. In Frankfurt am Main as well as digitally.

More information on Stratasys: https://www.stratasys.com/en/ + Stratasys develops industrial grade additive solutions to help you solve critical design and manufacturing challenges, right along your production cycle. Working with you to push the boundaries of what’s possible. And thrive in a changing world.

More information on Yoav Zeif (Director and Chief Executive Officer, Stratasys): https://investors.stratasys.com/company-information/management-team + https://www.linkedin.com/in/yoav-zeif-990117/

More information on LEAM Technologies: https://leam.tech/ + LEAM specializes in improving part quality and process stability in extrusion 3D printing through innovative temperature monitoring and localized remelting of undercooled areas. Utilizing contactless radiation, LEAM uses LEDs with a continuous wavelength spectrum in the visible range, offering a more efficient and safer alternative to traditional laser systems. Our core technology enables full welding between layers, achieving maximum material properties and enabling the transition of extrusion additive manufacturing from prototyping to serial production of end-use parts. LEAM provides a monitoring system and active temperature control, catering to professional users in industries where component quality and low failure rates are crucial. With a strategic focus on Large Format Additive Manufacturing systems, LEAM targets industries with a demand for large, high-quality components, such as Aerospace, Oil & Gas, and Defense, while also exploring opportunities in sectors utilizing technical polymers like Automotive, Marine, Architecture, and others. LEAM has been funded by the Exist Transfer of Research program of the German Federal Ministry for Economic Affairs and Climate Action and is part of the ESA Business Incubator Bavaria. This has enabled the development of a prototype demonstrating isotropic material properties in high-performance polymers like PEEK.

More information on Patrick Consul (Chief Executive Officer, LEAM Technologies): https://leam.tech/team + https://www.linkedin.com/in/patrick-consul/

More information on VLM Robotics: https://www.vlm-robotics.fr/index.php/vlm-en/ + VLM Robotics located in Gironde (33380), contributes to development to the development of industry 4.0 by the introduction of agile robotics.

This robotics allows solves a major issue for manufacturers : the fragmentation of their production in micro series and the swith to mass customization.

More information on Philippe Verlet (Chief Executive Officer, VLM Robotics): https://www.vlm-robotics.fr/index.php/vlm-en/ + https://www.linkedin.com/in/philippe-verlet-078529b7/

More information on Haddy: https://www.haddy.life/ + Environmentally Conscious Furniture.

Haddy is a 3D digital manufacturer serving retailers and commercial developers with all furniture needs. Our products are sustainable, designed, beautiful, and on time. We operate the world’s first regional, commercial-level microfactories, enabling local, on-demand production.

Haddy was founded on the principle that technology has the capacity to improve the longevity and quality of life on the planet. We consider this to be the intersection where design and nature both flourish and evolve, in balance with one another. Dedicated to achieving full circularity through its lineage model for additive manufacturing and using renewable and recycleable materials for all of our products, Haddy has built circularity into its foundation by upcycling products at end of use for the next generation of goods.

Our goal is to center people and the planet in all that we do. We envision a future for the furniture manufacturing industry that is kind to the planet, respectful to design, and honors the people who work to bring objects to life as well as those who live their lives upon them.

More information on John B. Rogers (Co-founder and Chief Executive Officer, Haddy): https://www.haddy.life/about-us + https://www.linkedin.com/in/johnbrogersjr/

More information on CEAD: https://ceadgroup.com/ + CEAD is headquartered in Delft, Netherlands, which is the hometown of one of Europe’s most prestigious technical universities. It’s not a coincidence that the company is rooted here, as the founders began their journey by developing a consumer 3D printer in 2010 while studying at this university.

After gaining this experience, the founders recognized the full potential of additive manufacturing and decided to pursue larger-scale solutions. As a result, in 2014, they established CEAD, which stands for Connecting Engineering and Design. Focusing on large-scale solutions, CEAD has been a pioneering force of innovation within the industry.

In 2017, the company patented the unique Continuous Fibre Additive Manufacturing (CFAM) technology, which allows for the high-speed fabrication of large-scale, continuous-fibre reinforced products. This invention demonstrates that innovation and passion for technology are at the core of CEAD’s values.

Today, the company has gained extensive experience designing and installing the world’s largest 3D printers. CEAD is committed to continuing to stay at the forefront of innovation, with the goal of accelerating innovation globally.

More information on Lucas Janssen (Chief Executive Officer, CEAD): https://ceadgroup.com/about-us/ + https://www.linkedin.com/in/lucas-janssen-110ab165/

More information on Smart Industry Readiness Index (SIRI) by Singapore Economic Development Board (EDB): https://www.edb.gov.sg/en/about-edb/media-releases-publications/advanced-manufacturing-release.html + The Smart Industry Readiness Index (SIRI) was created in Singapore, in partnership with a network of leading technology companies, consultancy firms, and industry, and academic experts. SIRI comprises a suite of frameworks and tools to help manufacturers – regardless of size and industry – start, scale, and sustain their manufacturing transformation journeys. SIRI covers the three core elements of Industry 4.0: Process, Technology, and Organisation.

As part of the World Economic Forum’s Global SIRI Initiative, the International Centre for Industrial Transformation (INCIT) was established in 2021 to bring SIRI to the next level. INCIT is a new, independent, non-governmental, not-for-profit organization that will take over management and coordination of the SIRI programme. Supported by the Forum and other international organizations, INCIT will work closely with partners from both the public and private sectors to catalyse industrial transformation at a global scale.

EMR Additional Notes:

- Industrial Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Fixed Automation:

- Fixed automation systems are utilized in high volume production settings that have dedicated equipment. The equipment has fixed operation sets and is designed to perform efficiently with the operation sets. This type of automation is mainly used in discrete mass production and continuous flow systems like paint shops, distillation processes, transfer lines and conveyors. All these processes rely on mechanized machinery to perform their fixed and repetitive operations to achieve high production volumes.

- Programmable Automation:

- Programmable automation systems facilitate changeable operation sequences and machine configuration using electronic controls. With programmable automation, non-trivial programming efforts are required to reprogram sequence and machine operations. Since production processes are not changed often, programmable automation systems tend to be less expensive in the long run. This type of system is mainly used in low job variety and medium-to-high product volume settings. It may also be used in mass production settings like paper mills and steel rolling mills.

- Flexible Automation:

- Flexible automation systems are utilized in computer-controlled flexible manufacturing systems. Human operators enter high-level commands in the form of computer codes that identify products and their location in the system’s sequence to trigger automatic lower-level changes. Every production machine receives instructions from a human-operated computer. The instructions trigger the loading and unloading of necessary tools before carrying out their computer-instructed processes. Once processing is completed, the end products are transferred to the next machine automatically. Flexible industrial automation is used in batch processes and job shops with high product varieties and low-to-medium job volumes.

- Integrated Automation:

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Computer-aided process planning

- Computer-supported design and manufacturing

- Flexible machine systems

- Computer numerical control machine tools

- Automated material handling systems, like robots

- Automatic storage and retrieval systems

- Computerized production and scheduling control

- Automated conveyors and cranes

- Additionally, an integrated automation system can integrate a business system via a common database. That is, it supports the full integration of management operations and processes using communication and information technologies. Such technologies are utilized in computer integrated manufacturing and advanced process automation systems.

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Fixed Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Process Automation / Manufacturing:

- Process automation is defined as the use of software and technologies to automate business processes and functions in order to accomplish defined organizational goals, such as producing a product, hiring and onboarding an employee, or providing customer service.

- Process manufacturing utilizes chemical, physical and compositional changes to convert raw material or feedstock into a product. Process manufacturing includes industries such as cement and glass, chemicals, electric power generation, food and beverage, life sciences, metals and mining, oil and gas, pulp and paper, refining, and water and wastewater. Process manufacturing includes both continuous and batch processes.

- Discrete Automation / Manufacturing:

- Discrete automation is the production of parts that are of a quantifiable nature. That may include cell phones, soda bottles, automobiles, airplanes, toys, etc. As you know, an automobile contains many, many parts. The parts required for an automobile are also quantifiable in nature.

- Discrete manufacturing processes include the production of individual parts as well as their assembly into a final product. Discrete manufacturing examples include automobiles, appliances, and consumer electronics.

- Hybrid Automation / Manufacturing:

- The Hybrid Automation Method follows two guiding principles: Implementing robust automation solutions that are easy and affordable for organisations to maintain. Realising process efficiency rapidly by reducing project overheads and time-to-value.

- Hybrid manufacturing is a combination of additive manufacturing (AM) and subtractive manufacturing within the same machine.

- Additive Manufacturing (AM):

- Additive manufacturing is the process of creating an object by building it one layer at a time. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final product is complete.

- Operators across a variety of different manufacturing industries utilize additive manufacturing in various ways. For instance: Medical device manufacturers use 3D printing to develop high variance products such as dental implants.

- The term “additive manufacturing” refers to the creation of objects by “adding” material. Therefore, 3D printing is a form of additive manufacturing. When an object is created by adding material — as opposed to removing material — it’s considered additive manufacturing.

- Smart Manufacturing (SM):

- Technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of SM is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

- An example of what the cloud can do for smart manufacturing is the Volkswagen Industrial Cloud, which combines all data from 122 Volkswagen Group facilities and processes it in real time to make improvements.

- Circular Economy:

- A circular economy is a systemic approach to economic development designed to benefit businesses, society, and the environment. In contrast to the ‘take-make-waste’ linear model, a circular economy is regenerative by design and aims to gradually decouple growth from the consumption of finite resources.

- In such an economy, all forms of waste, such as clothes, scrap metal and obsolete electronics, are returned to the economy or used more efficiently.

- The aim of a circular economy is hence to create a closed-loop system where waste and pollution are minimized and resources are conserved, reducing the environmental impact of production and consumption.

- Sustainability Vs. Circular Economy:

- Circularity focuses on resource cycles, while sustainability is more broadly related to people, the planet and the economy. Circularity and sustainability stand in a long tradition of related visions, models and theories.

- A sustainable circular economy involves designing and promoting products that last and that can be reused, repaired and remanufactured. This retains the functional value of products, rather than just recovering the energy or materials they contain and continuously making products anew.

- CNC (Computer Numerical Control):

- CNC machining is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts.

- Digital Threads:

- A digital thread is the flow of information about a product’s performance and use from design to production, sale, use and disposal or recycling. This provides insights into how customers use products, how those products perform, how they could be improved and what new features customers might want.

- Digital Twin:

- Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimize through real time analytics to deliver business value.

- A digital twin is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making.

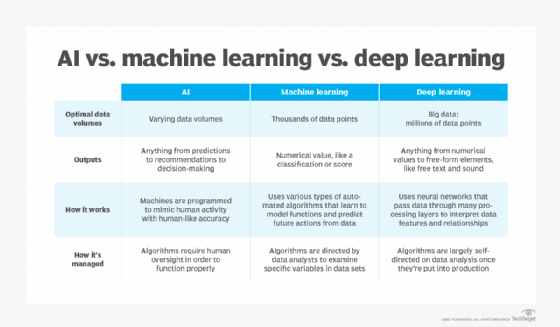

- AI – Artificial Intelligence:

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but well a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

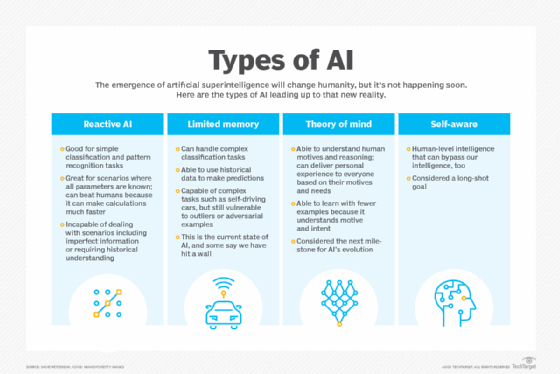

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.

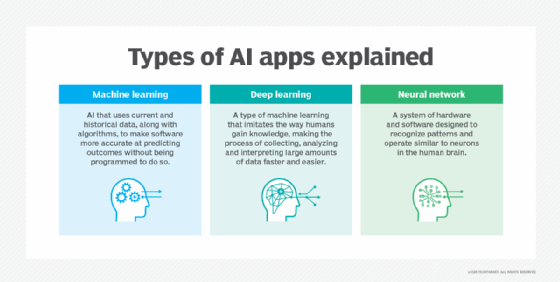

- Machine Learning (ML):

- Developed to mimic human intelligence, it lets the machines learn independently by ingesting vast amounts of data, statistics formulas and detecting patterns.

- ML allows software applications to become more accurate at predicting outcomes without being explicitly programmed to do so.

- ML algorithms use historical data as input to predict new output values.

- Recommendation engines are a common use case for ML. Other uses include fraud detection, spam filtering, business process automation (BPA) and predictive maintenance.

- Classical ML is often categorized by how an algorithm learns to become more accurate in its predictions. There are four basic approaches: supervised learning, unsupervised learning, semi-supervised learning and reinforcement learning.

- Deep Learning (DL):

- Subset of machine learning, Deep Learning enabled much smarter results than were originally possible with ML. Face recognition is a good example.

- DL makes use of layers of information processing, each gradually learning more and more complex representations of data. The early layers may learn about colors, the next ones about shapes, the following about combinations of those shapes, and finally actual objects. DL demonstrated a breakthrough in object recognition.

- DL is currently the most sophisticated AI architecture we have developed.

- Computer Vision (CV):

- Computer vision is a field of artificial intelligence that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs — and take actions or make recommendations based on that information.

- The most well-known case of this today is Google’s Translate, which can take an image of anything — from menus to signboards — and convert it into text that the program then translates into the user’s native language.

- Machine Vision (MV):

- Machine Vision is the ability of a computer to see; it employs one or more video cameras, analog-to-digital conversion and digital signal processing. The resulting data goes to a computer or robot controller. Machine Vision is similar in complexity to Voice Recognition.

- MV uses the latest AI technologies to give industrial equipment the ability to see and analyze tasks in smart manufacturing, quality control, and worker safety.

- Computer Vision systems can gain valuable information from images, videos, and other visuals, whereas Machine Vision systems rely on the image captured by the system’s camera. Another difference is that Computer Vision systems are commonly used to extract and use as much data as possible about an object.

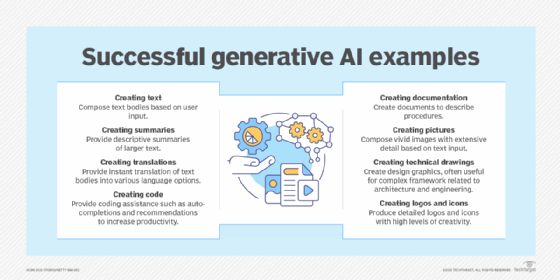

- Generative AI (GenAI):

- Generative AI technology generates outputs based on some kind of input – often a prompt supplied by a person. Some GenAI tools work in one medium, such as turning text inputs into text outputs, for example. With the public release of ChatGPT in late November 2022, the world at large was introduced to an AI app capable of creating text that sounded more authentic and less artificial than any previous generation of computer-crafted text.

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Edge AI Technology:

- Edge artificial intelligence refers to the deployment of AI algorithms and AI models directly on local edge devices such as sensors or Internet of Things (IoT) devices, which enables real-time data processing and analysis without constant reliance on cloud infrastructure.

- Simply stated, edge AI, or “AI on the edge“, refers to the combination of edge computing and artificial intelligence to execute machine learning tasks directly on interconnected edge devices. Edge computing allows for data to be stored close to the device location, and AI algorithms enable the data to be processed right on the network edge, with or without an internet connection. This facilitates the processing of data within milliseconds, providing real-time feedback.

- Self-driving cars, wearable devices, security cameras, and smart home appliances are among the technologies that leverage edge AI capabilities to promptly deliver users with real-time information when it is most essential.

- Multimodal Intelligence and Agents:

- Subset of artificial intelligence that integrates information from various modalities, such as text, images, audio, and video, to build more accurate and comprehensive AI models.

- Multimodal capabilities allows to interact with users in a more natural and intuitive way. It can see, hear and speak, which means that users can provide input and receive responses in a variety of ways.

- An AI agent is a computational entity designed to act independently. It performs specific tasks autonomously by making decisions based on its environment, inputs, and a predefined goal. What separates an AI agent from an AI model is the ability to act. There are many different kinds of agents such as reactive agents and proactive agents. Agents can also act in fixed and dynamic environments. Additionally, more sophisticated applications of agents involve utilizing agents to handle data in various formats, known as multimodal agents and deploying multiple agents to tackle complex problems.

- Small Language Models (SLM) and Large Language Models (LLM):

- Small language models (SLMs) are artificial intelligence (AI) models capable of processing, understanding and generating natural language content. As their name implies, SLMs are smaller in scale and scope than large language models (LLMs).

- LLM means large language model—a type of machine learning/deep learning model that can perform a variety of natural language processing (NLP) and analysis tasks, including translating, classifying, and generating text; answering questions in a conversational manner; and identifying data patterns.

- For example, virtual assistants like Siri, Alexa, or Google Assistant use LLMs to process natural language queries and provide useful information or execute tasks such as setting reminders or controlling smart home devices.

- Metaverse:

- The first use of the term ‘metaverse’ was in the 1992 science fiction novel “Snow Crash”, by Neal Stephenson, which described a single virtual world separate from the physical world.

- In the broadest terms, the metaverse is understood as a graphically rich virtual space, with some degree of verisimilitude, where people can work, play, shop, socialize — in short, do the things humans like to do together in real life (or, perhaps more to the point, on the internet).

- The technologies companies refer to when they talk about “the metaverse” can include virtual reality—characterized by persistent virtual worlds that continue to exist even when you’re not playing—as well as augmented reality that combines aspects of the digital and physical worlds.

- Basically, a place parallel to the physical world, where you spend your digital life. A place where you and other people have an avatar, and you interact with them through their avatars.

- The Metaverse represents a highly interactive three-dimensional virtual world. Like the real world, users can trade land, buildings, and other digital assets in the Metaverse and explore the space using their personalized avatars.

- Examples: Hyundai Motor Company debuted Hyundai Mobility Adventure, a metaverse experience on gaming platform Roblox. Gamers’ avatars can experience Hyundai future mobility projects and current products. And last year, Warner Bros. Pictures hosted a virtual party on Roblox to market its movie In the Heights.

- Bloomberg Intelligence tells us that the value of the metaverse is expected to reach $800 billion by the middle 2020s with that figure climbing to $2.5 trillion by 2030.

- Following Meta, the metaverse is the next evolution in social connection and the successor to the mobile Internet.

- Industrial Metaverse:

- The industrial metaverse is a network of digital twins that links physical assets and the digital world. It enables manufacturers to connect their digital twins with their customers and suppliers so they can work together and get insights based on real time data.

- On one side, we have Industry 4.0 (Industrial IoT or IIoT) which has been gathering data from equipment and environments for many years. This data is increasingly stored in the cloud and accessed through an off-the-shelf IoT provider, such as Amazon’s AWS or Microsoft’s Azure. On the other side, we have the 3D world of gaming technology, augmented/virtual/mixed realities, and CAD. Combining the two leads to an immersive environment where IoT data can be accessed in new and innovative ways.

- Digital worlds based on real-time data will allow corporations to have multiple iterations and simulations of themselves. Lessons learned and breakthroughs discovered in the Industrial Metaverse will provide feedback into reality, enabling companies to change real-world parameters to optimise everything!

- The Industrial Metaverse is “basically” a Digital Twin

- Simulations in a metaverse environment could allow manufacturers to test thousands of potential scenarios for their ecosystems to explore different strategies.

- RFID (Radio Frequency Identification):

- RFID is a form of wireless communication that incorporates the use of electromagnetic or electrostatic coupling in the radio frequency portion of the electromagnetic spectrum to uniquely identify an object, animal or person.

- Radio Frequency Identification (RFID) refers to a wireless system comprised of two components: tags and readers. The reader is a device that has one or more antennas that emit radio waves and receive signals back from the RFID tag.

- RFID tags are a type of tracking system that uses radio frequency to search, identify, track, and communicate with items and people. Essentially, RFID tags are smart labels that can store a range of information from serial numbers, to a short description, and even pages of data.

- API (Application Programming Interface):

- A set of definitions and protocols to build and integrate application software. Software intermediary that allows two applications to talk to each other. Each time you use an app like Facebook, send an instant message, or check the weather on your phone, you’re using an API.

- APIs are needed to bring applications together in order to perform a designed function built around sharing data and executing pre-defined processes. They work as the middle man, allowing developers to build new programmatic interactions between the various applications people and businesses use on a daily basis.

- There are four principal types of API commonly used in web-based applications: public, partner, private and composite

- Industry 4.0:

- Industry 4.0 has been defined as “a name for the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of things, cloud computing and cognitive computing and creating the smart factory”.

- Industry 4.0 aims at transforming the manufacturing and engineering sectors by introducing factories where cyber-processing systems communicate over the Internet of Things, assisting people and machinery to execute their tasks within the shortest time possible.

- Industry 4.0 technology helps you manage and optimize all aspects of your manufacturing processes and supply chain. It gives you access to the real-time data and insights you need to make smarter, faster decisions about your business, which can ultimately boost the efficiency and profitability of your entire operation.

- The Fourth Industrial Revolution (4IR) is a term coined in 2016 by Klaus Schwab, Founder and Executive Chairman of the World Economic Forum (WEF).

- 4 Industrial Revolutions:

- First Industrial Revolution: Coal in 1765.

- Second Industrial Revolution: Gas in 1870.

- Third Industrial Revolution: Electronics and Nuclear in 1969.

- Fourth Industrial Revolution: Internet and Renewable Energy in 2000.

- Industry 5.0:

- The Fifth Industrial Revolution, or 5IR, encompasses the notion of harmonious human–machine collaborations, with a specific focus on the well-being of the multiple stakeholders (i.e., society, companies, employees, customers)

- The term Industry 5.0 refers to people working alongside robots and smart machines. It’s about robots helping humans work better and faster by leveraging advanced technologies like the Internet of Things (IoT) and big data. It adds a personal human touch to the Industry 4.0 pillars of automation and efficiency.

- Industry 5.0 takes a sharp turn and directs attention to the human element. It also ‘reflects a shift from a focus on economic value to a focus on societal value, and a shift in focus from welfare to wellbeing’ (Forbes). Compared to Industry 4.0, Industry 5.0 is…

- Dedicated to both customer and employee experience

- Acknowledging social and economic challenges

- Putting great attention on human well-being and sustainability

- Providing ‘a vision of industry that aims beyond efficiency and productivity as the sole goals’ (European Commission)

- It complements the existing “Industry 4.0” approach by specifically putting research and innovation at the service of the transition to a sustainable, human-centric and resilient industry.