ABB – ABB acquires Sevensense, expanding leadership in next-generation AI-enabled mobile robotics

- Swiss start-up Sevensense, a leader in AI-based navigation, enables the highest levels of speed, accuracy and autonomy of mobile robots, one of the fastest growing robotics markets

- Acquisition underlines ABB’s strategic investment focus on innovative AI solutions transforming industries, such as logistics and manufacturing

- ABB becomes leader in next-generation AMRs, integrating Visual SLAM technology with leading hardware and software portfolio

ABB today announced that it has acquired Swiss start-up Sevensense, a leading provider of AI-enabled 3D vision navigation technology for autonomous mobile robots (AMRs). Sevensense was founded in 2018 as a spin-off from Swiss technical University, ETH Zurich.

“This marks a significant step towards our vision of a workplace where AI-enabled robots assist people, addressing our customers’ needs for greater flexibility and intelligence amidst critical skilled labor shortages,” said Sami Atiya, President of ABB Robotics and Discrete Automation. “Each mobile robot, equipped with vision and AI, scans a unique part of the building; collectively these robots complement each other’s view to form a complete map, enabling them to work autonomously in a rapidly changing environment.”

The acquisition follows ABB’s minority investment in Sevensense after it joined the company’s innovation ecosystem in 2021, the same year ABB acquired ASTI Mobile Robotics. Financial details of the transaction were not disclosed. Following pilot customer projects in the automotive and logistics industries, ABB will integrate Sevensense’s technology into the company’s AMR portfolio, offering an unprecedented combination of speed, accuracy, and payload.

The market for mobile robots is expected to grow at 20 percent CAGR through 2026, from $5.5bn to $9.5bn and ABB’s AI-powered 3D vision technology is at the forefront of this growth.1

Sevensense’s pioneering navigation technology combines AI and 3D vision, enabling AMRs to make intelligent decisions, differentiating between fixed and mobile objects in dynamic environments. Once manually guided, mobile robots with Visual Simultaneous Localization and Mapping (Visual SLAM) technology create a map that is used to operate independently, reducing commissioning time from weeks to days and enabling the AMRs to navigate in highly complex, dynamic environments alongside people. Maps are constantly updated and shared across the fleet, offering instant scalability without interrupting operations and greater flexibility compared to other navigation technologies.

Today, this AI-enabled navigation technology is already transforming the automotive manufacturing and logistics sectors, delivering value through faster and more efficient operations. For automotive manufacturer Ford, Visual SLAM enabled ABB AMR’s will create efficiency gains in production sites in the US, while Michelin will use the technology in intralogistics at its factory in Spain. Other automotive manufacturers will roll out the technology in the UK, Finland and Germany.

“Offering more autonomy and cognitive intelligence, ABB’s unique market-proven technology paves the way for a shift from linear production lines to dynamic networks. Intelligent AMRs autonomously navigate to production cells, tracking stock inventory as they go and sharing this information with other robots, while collaborating safely side-by-side with humans,” said Marc Segura, President of ABB’s Robotics Division. “With the acquisition of Sevensense, ABB becomes the leader in next-generation AMRs, offering Visual SLAM in Autonomous Mobile Robots, together with an integrated portfolio covering robots and machine automation solutions, all managed by our value-creating software.”

Gregory Hitz, CEO of Sevensense, said: “This is a significant moment in our shared journey, as we introduce our home-grown technology to a wider range of markets and sectors. ABB is the ideal home for us to continue scaling our versatile platform for 3D visual autonomy, serving OEMs across the automated material handling and service robotics industries. Together, we will redefine the limits of AI-enabled robotics.”

This revolutionary technology has the potential to impact robotics far beyond AMRs, leading to greater efficiency, flexibility and accuracy throughout production and intralogistics. The technology will also continue to be sold across segments including material handling, cleaning and other service robotics fields under the product name Sevensense.

The Sevensense partnership highlights the success of ABB’s commitment to nurturing the next generation of innovations. Through its partner ecosystem and collaboration with start-ups and universities, ABB develops leading technology for the benefit of global businesses. Sevensense’s approximately 35 employees will continue to be based at its Swiss office in Zurich.

- ABB analysis

SourceABB

EMR Analysis

More information on ABB: See full profile on EMR Executive Services

More information on Björn Rosengren (Chief Executive Officer, ABB): See full profile on EMR Executive Services

More information on ABB Robotics & Discrete Automation: https://new.abb.com/products/robotics + ABB Robotics & Discrete Automation is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors – from automotive to electronics and logistics – become more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future. The business area employs approximately 11,000 people at over 250 locations in more than 50 countries.

More information on Sami Atiya (President, Robotics & Discrete Automation and Member of the Executive Committee, ABB): See full profile on EMR Executive Services

More information on Marc Segura (President, ABB Robotics, ABB): See full profile on EMR Executive Services

More information on Sevensense: https://www.sevensense.ai/ + Sevensense was founded in 2018 as a spin-off from the Swiss Federal Institute of Technology, ETH Zurich. Our technology is based on 15+ years of research and the vast, hands-on experience at the Autonomous Systems Lab paved our way towards reliable localization, path planning and operation of mobile robots.

In 2018, Sevensense became a Wyss Zurich project, with the goal of translating those technological advancements into an industry-grade product ready to be deployed on any mobile robot. Since then, our team is in continuous expansion and motivated to revolutionize the mobile robotics industry.

Sevensense empowers mobile robots to move into public and dynamic spaces. With our technology they will support humans in the execution of dirty, dangerous and dull tasks.

We do so using Alphasense Autonomy, our versatile autonomy kit, that turns mobile platforms into intelligent robots. By using Edge AI and state-of-the-art technologies, our solution guarantees reliability and safety, bringing the operational costs down and opening new, exciting market opportunities.

Our Visual AI technology enables OEMs to build mobile robots that move autonomously in challenging and dynamic environments and serve new use-cases, making it possible for robots to safely and efficiently complete difficult tasks.

Sevensense’s pioneering navigation technology combines AI and 3D vision, enabling AMRs to make intelligent decisions, differentiating between fixed and mobile objects in dynamic environments. Once manually guided, mobile robots with Visual Simultaneous Localization and Mapping (Visual SLAM) technology create a map that is used to operate independently, reducing commissioning time from weeks to days and enabling the AMRs to navigate in highly complex, dynamic environments alongside people. Maps are constantly updated and shared across the fleet, offering instant scalability without interrupting operations and greater flexibility compared to other navigation technologies.

Sevensense has approximately 35 employees.

More information on Gregory Hitz (Co-founder and Chief Executive Officer, Sevensense, ABB): See full profile on EMR Executive Services

More information on ETH Zürich: https://ethz.ch/en.html + Freedom and individual responsibility, entrepreneurial spirit and open-mindedness: ETH Zurich stands on a bedrock of true Swiss values. Our university for science and technology dates back to the year 1855, when the founders of modern-day Switzerland created it as a centre of innovation and knowledge.

At ETH Zurich, students discover an ideal environment for independent thinking, researchers a climate which inspires top performance. Situated in the heart of Europe, yet forging connections all over the world, ETH Zurich is pioneering effective solutions to the global challenges of today and tomorrow.

More information on Prof. Dr. Joël Mesot (President, ETH Zürich): https://www.phys.ethz.ch/the-department/people/person-detail.Mzc5NDU=.TGlzdC84MzgsMTE3MjU5OTI5OQ==.html + https://www.linkedin.com/in/jo%C3%ABl-mesot-03922228/

More information on ASTI Mobile Robotics Group: https://www.astimobilerobotics.com + https://new.abb.com/products/robotics/robots/autonomous-mobile-robots + ASTI Mobile Robotics is an international group of mobile robotics companies whose aim it is to help its customers become more competitive. Our engineering team analyses, designs, manufactures, deploys and maintains AGV-based intralogistics systems used to move materials and products from one location to another within plants.

Offering the market’s widest range of automated guided vehicles (AGVs), ASTI Mobile Robotics Group has been awarded Europe’s leading mobile robotics manufacturer for the fifth consecutive year. We are an expert in industrial connectivity and mobile robotics data analytics.

With a history stretching back more than 35 years, ASTI MR Group is part of ASTI TechGroup, a technology and digital transformation holding,which includes ASTI Mobile Robotics Group and, aware of the challenges that digital transformation brings, ASTI Talent & Tech Foundation (which promotes STEM vocations among young people through programs like STEM Talent Kids, STEM Talent Girl and ASTI Challenge).

ASTI MR Group comprises of ASTI Mobile Robotics, ASTI Mobile Robotics France and ASTI Mobile Robotics Germany. ASTI MR Group had a workforce of over 300 employees as of 2020 and plants located in Burgos (Spain), Madrid (Spain), Berlin (Germany), Mulhouse (France) and Washington (North Carolina, USA).

More information on Ford Motor Company: https://www.ford.com/ + Ford Motor Company (NYSE: F) is a global company based in Dearborn, Michigan, that is committed to helping build a better world, where every person is free to move and pursue their dreams. The company’s Ford+ plan for growth and value creation combines existing strengths, new capabilities and always-on relationships with customers to enrich experiences for and deepen the loyalty of those customers. Ford designs, manufactures, markets and services a full line of connected, increasingly electrified passenger and commercial vehicles: Ford trucks, utility vehicles, vans and cars, and Lincoln luxury vehicles. The company is pursuing leadership positions in electrification, connected vehicle services and mobility solutions, including self-driving technology, and provides financial services through Ford Motor Credit Company. Ford employs about 183,000 people worldwide

More information on James D. Farley, Jr. (Chief Executive Officer, Ford Motor Company): https://corporate.ford.com/about/leadership.html + https://www.linkedin.com/in/jim-farley/

More information on the Michelin Group: https://www.michelin.com/en/ + As the technology leader in tires for all forms of mobility, Michelin has structured its business base around three core segments – tires, tire-related fleet services, and high-tech materials – with the double objective of strengthening its technological leadership in tires and expanding in high-potential growth territories to leverage its unique capabilities in new ways.

Operating in a wide variety of markets not only enables the Group to diversify its sources of revenue but also to capitalize on the countercyclical nature of certain industries or business segments to strengthen its resilience. Today, tire-related sales account for nearly 95% of the consolidated total, divided almost equally between B2C (replacement passenger car and two-wheeler tires) and B2B sales (Road transportation, Beyond road, Mining, Automotive original equipment, and Aircraft). The main targeted growth drivers are focused on the shift to electric mobility and specialty tires. The Group also intends to expand in services and solutions for vehicle fleets by capitalizing on advances in digital technology and connected mobility. It also leverages its unrivaled expertise in high-tech materials and leading-edge industrial processes in a variety of industries, including energy, medical devices and aerospace. Non-tire sales rose by 22% in 2022.

- 2022 Revenue: € 28.6bn

- 132,000 Employees

- 121 Facilities in 26 countries

More information on Florent Menegaux (Chief Executive Officer, Michelin Group): https://www.michelin.com/en/michelin-group/governance/executive-biographies/ + https://www.linkedin.com/in/florent-menegaux/

EMR Additional Notes:

- AI – Artificial Intelligence:

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

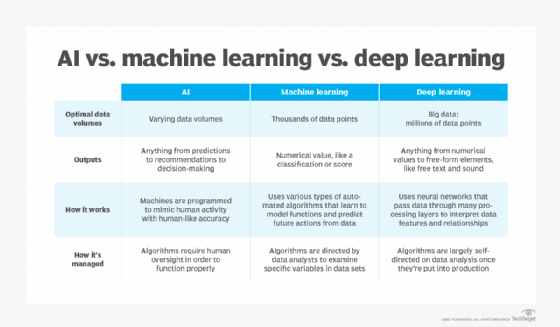

- Artificial intelligence is the simulation of human intelligence processes by machines, especially computer systems. Specific applications of AI include expert systems, natural language processing, speech recognition and machine vision.

- As the hype around AI has accelerated, vendors have been scrambling to promote how their products and services use AI. Often what they refer to as AI is simply one component of AI, such as machine learning. AI requires a foundation of specialized hardware and software for writing and training machine learning algorithms. No one programming language is synonymous with AI, but a few, including Python, R and Java, are popular.

- In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text chats can learn to produce lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples.

- AI programming focuses on three cognitive skills: learning, reasoning and self-correction.

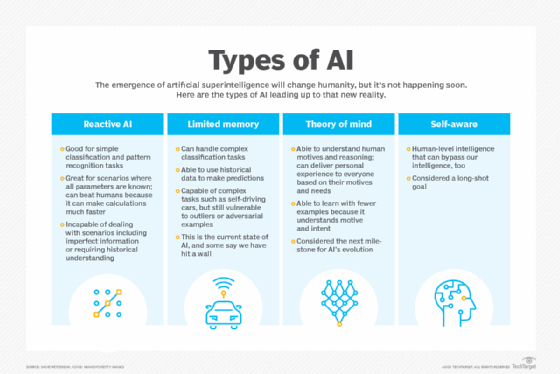

- What are the 4 types of artificial intelligence?

- Type 1: Reactive machines. These AI systems have no memory and are task specific. An example is Deep Blue, the IBM chess program that beat Garry Kasparov in the 1990s. Deep Blue can identify pieces on the chessboard and make predictions, but because it has no memory, it cannot use past experiences to inform future ones.

- Type 2: Limited memory. These AI systems have memory, so they can use past experiences to inform future decisions. Some of the decision-making functions in self-driving cars are designed this way.

- Type 3: Theory of mind. Theory of mind is a psychology term. When applied to AI, it means that the system would have the social intelligence to understand emotions. This type of AI will be able to infer human intentions and predict behavior, a necessary skill for AI systems to become integral members of human teams.

- Type 4: Self-awareness. In this category, AI systems have a sense of self, which gives them consciousness. Machines with self-awareness understand their own current state. This type of AI does not yet exist.

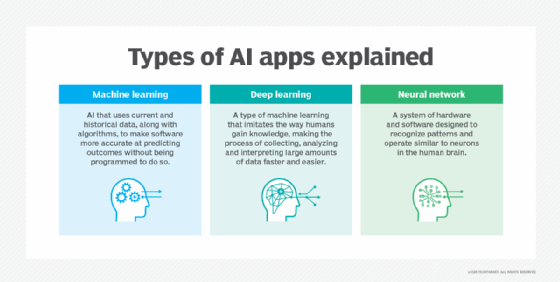

- Machine Learning:

- Developed to mimic human intelligence. It lets the machines learn independently by ingesting vast amounts of data and detecting patterns. Many ML algorithms use statistics formulas and big data to function.

- Type of artificial intelligence (AI) that allows software applications to become more accurate at predicting outcomes without being explicitly programmed to do so. Machine learning algorithms use historical data as input to predict new output values.

- Recommendation engines are a common use case for machine learning. Other popular uses include fraud detection, spam filtering, malware threat detection, business process automation (BPA) and Predictive maintenance.

- Classical machine learning is often categorized by how an algorithm learns to become more accurate in its predictions. There are four basic approaches: supervised learning, unsupervised learning, semi-supervised learning and reinforcement learning. The type of algorithm data scientists choose to use depends on what type of data they want to predict.

- Deep Learning:

- Subset of machine learning. Deep learning enabled much smarter results than were originally possible with machine learning. Consider the face recognition example.

- Deep learning makes use of layers of information processing, each gradually learning more and more complex representations of data. The early layers may learn about colors, the next ones learn about shapes, the following about combinations of those shapes, and finally actual objects. Deep learning demonstrated a breakthrough in object recognition.

- Deep learning is currently the most sophisticated AI architecture we have developed.

- Computer Vision:

- Computer vision is a field of artificial intelligence (AI) that enables computers and systems to derive meaningful information from digital images, videos and other visual inputs — and take actions or make recommendations based on that information.

- The most well-known case of this today is Google’s Translate, which can take an image of anything — from menus to signboards — and convert it into text that the program then translates into the user’s native language.

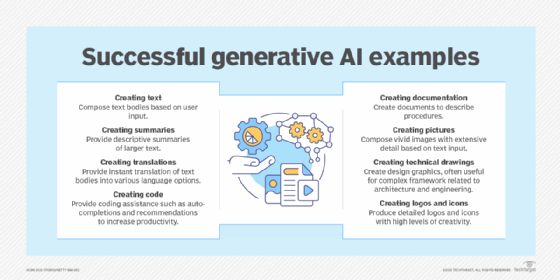

- Generative AI:

- Generative AI technology generates outputs based on some kind of input – often a prompt supplied by a person. Some GenAI tools work in one medium, such as turning text inputs into text outputs, for example. With the public release of ChatGPT in late November 2022, the world at large was introduced to an AI app capable of creating text that sounded more authentic and less artificial than any previous generation of computer-crafted text.

- https://searchenterpriseai.techtarget.com/definition/AI-Artificial-Intelligence +

- Edge AI Technology:

- Edge artificial intelligence refers to the deployment of AI algorithms and AI models directly on local edge devices such as sensors or Internet of Things (IoT) devices, which enables real-time data processing and analysis without constant reliance on cloud infrastructure.

- Simply stated, edge AI, or “AI on the edge“, refers to the combination of edge computing and artificial intelligence to execute machine learning tasks directly on interconnected edge devices. Edge computing allows for data to be stored close to the device location, and AI algorithms enable the data to be processed right on the network edge, with or without an internet connection. This facilitates the processing of data within milliseconds, providing real-time feedback.

- Self-driving cars, wearable devices, security cameras, and smart home appliances are among the technologies that leverage edge AI capabilities to promptly deliver users with real-time information when it is most essential.

- Cobots (Collaborative Robots):

- A collaborative robot, also known as a cobot, is a robot that is capable of learning multiple tasks so it can assist human beings. In contrast, autonomous robots are hard-coded to repeatedly perform one task, work independently and remain stationary.

- Intended to work hand-in-hand with employees. These machines focus more on repetitive tasks, such as inspection and picking, to help workers focus more on tasks that require problem-solving skills.

- A robot is an autonomous machine that performs a task without human control. A cobot is an artificially intelligent robot that performs tasks in collaboration with human workers.

- According to ISO 10218 part 1 and part 2, there are four main types of collaborative robots: safety monitored stop, speed and separation, power and force limiting, and hand guiding.

- Autonomous Mobile Robot (AMR):

- Any robot that can understand and move through its environment without being overseen directly by an operator or on a fixed predetermined path. AMRs have an array of sophisticated sensors that enable them to understand and interpret their environment, which helps them to perform their task in the most efficient manner and path possible, navigating around fixed obstructions (building, racks, work stations, etc.) and variable obstructions (such as people, lift trucks, and debris). Though similar in many ways to automated guided vehicles (AGVs), AMRs differ in a number of important ways. The greatest of these differences is flexibility: AGVs must follow much more rigid, preset routes than AMRs. Autonomous mobile robots find the most efficient route to achieve each task, and are designed to work collaboratively with operators such as picking and sortation operations, whereas AGVs typically do not.

- Automated Guided Vehicles (AGV):

- An AGV system, or automated guided vehicle system, otherwise known as an automatic guided vehicle, autonomous guided vehicle or even automatic guided cart, is a system which follows a predestined path around a facility.

- Three types of AGVs are towing, fork trucks, and heavy load carriers. Each is designed to perform repetitive actions such as delivering raw materials, keep loads stable, and complete simple tasks.

- The main difference between an AGV and an AMR is that AMRs use free navigation by means of lasers, while AGVs are located with fixed elements: magnetic tapes, magnets, beacons, etc. So, to be effective, they must have a predictable route.

- Visual SLAM Technology:

- SLAM (simultaneous localization and mapping) is a method used for autonomous vehicles that lets you build a map and localize your vehicle in that map at the same time. SLAM algorithms allow the vehicle to map out unknown environments.

- Software vs. Hardware vs. Firmware:

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Since hardware is part of the “real” world, it all eventually wears out. Being a physical thing, it’s also possible to break it, drown it, overheat it, and otherwise expose it to the elements.

- Here are some examples of hardware:

- Smartphone

- Tablet

- Laptop

- Desktop computer

- Printer

- Flash drive

- Router

- Software is virtual: It can be copied, changed, and destroyed.

- Software is everything about your computer that isn’t hardware.

- Here are some examples of software:

- Operating systems like Windows 11 or iOS

- Web browsers

- Antivirus tools

- Adobe Photoshop

- Mobile apps

- Firmware is virtual: It’s software specifically designed for a piece of hardware

- While not as common a term as hardware or software, firmware is everywhere—on your smartphone, your PC’s motherboard, your camera, your headphones, and even your TV remote control.

- Firmware is just a special kind of software that serves a very narrow purpose for a piece of hardware. While you might install and uninstall software on your computer or smartphone on a regular basis, you might only rarely, if ever, update the firmware on a device, and you’d probably only do so if asked by the manufacturer, probably to fix a problem.

- Hardware is physical: It’s “real,” sometimes breaks, and eventually wears out.

- Intralogistics:

- Intralogistics is the art of optimizing, integrating, automating, and managing the logistical flow of information and material goods within the walls of a fulfillment or distribution center.

- If logistics is defined as moving things efficiently from point A to point B, then intralogistics is a similar but much-expanded concept. It involves, within a distribution centre or warehouse, optimizing and managing the logistical flow of information along with physical materials management.

- OEM (Original Equipment Manufacturer):

- Company that produces parts and equipment that may be marketed by another manufacturer.

- Usually tagged on hardware or software that’s less expensive than normal retail products.

- An OEM refers to something made specifically for the original product, while the aftermarket refers to equipment made by another company that a consumer may use as a replacement.

- Electrical OEM manufacturers makes equipment or components that are then utilized by its customer, another manufacturer or a reseller, usually under the final reseller’s brand name. OEMs come in many shapes and sizes, making complete devices or specific components.

- MRO (Maintenance, Repair and Operations):

- It refers to all the activities needed to keep a company’s facilities and production processes running smoothly.

- Supplies consumed in the production process that do not become part of the end product.

- Maintenance professionals use MRO items to maintain company structures, equipment, and assets. Purchases that fall under MRO include maintenance tools and equipment, replacement parts for production equipment, consumables such as personal protective equipment (e.g., safety goggles, work gloves), cleaning products and office supplies.

- Integrated Supply:

- Integrated supply chain management refers to an enterprise resource planning approach to supply chain management.

- Large-scale business strategy that brings as many links of the chain as possible into a closer working relationship with each other. The goal is to improve response time, production time, and reduce costs and waste.

- Often takes the form of integrated computer systems. For example, the supplier’s computer system may be set up to deliver real-time data to the buyer’s computer. This allows the buyer to know: The current status of all orders., which products are in the supplier’s inventory …

- Integration, operations, purchasing and distribution are the four elements of the supply chain that work together to establish a path to competition that is both cost-effective and competitive.

- Integrated supply is the end-to-end process of managing the MRO supply chain (spare parts) through consolidated sourcing practices, storeroom operations, inventory management, data governance, and continuous improvement. The objective is to leverage spend, reduce transactions, and cut inventory and associated costs while eliminating risk around critical spares.