Assemblin Caverion Group – MTU Aero Engines AG extends its partnership with Caverion in Germany

Caverion continues to be responsible for the technical facility management at MTU Aero Engines’ Munich site for another contract period.

The contract is a continuation of a long partnership already over 10 years.

Caverion’s onsite team covers technical maintenance of building systems, such as heating, plumbing, air conditioning, refrigeration, ventilation and technical gases, building automation and electricity. The total area of the site is around 400,000 m².

As MTU Aero Engines’ partner, Caverion will continue to support them in meeting their greenhouse gas reduction targets at the Munich site. By 2030, MTU Aero Engines aims to reduce their emissions at all their sites by 60% compared to the reference year 2019. Based on regular energy inspections and energy audits conducted by Caverion, experts can identify potential energy savings at the site and opportunities for modern systems in existing buildings.

“Caverion is a trusted partner for us, and we appreciate the service team’s many years of experience and deep understanding of the requirements we face in production,” says Paul Koop, Senior Manager of Technical Facility Management, MTU Aero Engines.

“Our team has strong expertise in technical facility management, which ensures high quality of services. We are confident that we are the right partner for MTU Aero Engines in the complex challenges at the Munich site in the future too,” adds Manfred Simmet, EVP and CEO, Caverion Germany.

SourceAssemblin Caverion Group

EMR Analysis

More information on Assemblin Caverion Group: See the full profile on EMR Executive Services

More information on Jacob Götzsche (Executive Chairman, Assemblin Caverion Group + Member of the Executive Committee (EC) and Member of the Executive Management Team (EMT), Executive Chairman, Assemblin Caverion Group + President and Chief Executive Officer, Caverion Corporation): See the full profile on EMR Executive Services

More information on Mats Johansson (Member of the Executive Committee (EC) and Member of the Executive Management Team (EMT), Group President and Chief Executive Officer, Assemblin Caverion Group): See the full profile on EMR Executive Services

More information on Manfred Simmet (Member of the Executive Committee (EC) and Member of the Executive Management Team (EMT), Executive Vice President, Chief Executive Officer, Caverion Austria & Germany, Assemblin Caverion): See the full profile on EMR Executive Services

More information on MTU Aero Engines AG: https://www.mtu.de/ + Three letters stand for world-class technology in aviation: MTU. We are a globally recognized specialist for commercial and military propulsion systems – a true global player with multinational teams and strong roots in Germany. MTU is where passion for flying meets high-tech engine expertise.

We are a technology leader for innovative engines.

MTU Aero Engines is the expert of choice in the design, development, manufacture and mainte-nance of commercial and military engines – in all thrust and power categories – and of stationary industrial gas turbines. Our passion for aviation drives us to make flying safer, more efficient, and more sustainable. We’re building on our technological expertise to enable emissions-free flight in the future – a vision that we’re driving forward with revolutionary developments. This enthusiasm for technology and innovation is our DNA, and the reason why we’re regarded as an indispensable partner worldwide. In addition, we play a key role in national security and sovereignty in Europe with next-generation military propulsion systems.

More information on Lars Wagner (Chief Executive Officer, MTU Aero Engines AG): https://www.mtu.de/about-us/corporate-governance/executive-board/ + https://www.linkedin.com/in/lars-wagner-mtu/

More information on Paul Koop (Senior Manager, Technical Facility Management, MTU Aero Engines AG): N.A.

EMR Additional Notes:

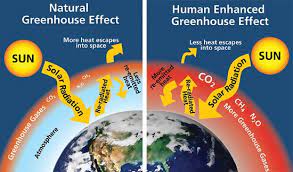

- Global Warming:

- Global warming is the long-term heating of Earth’s climate system observed since the pre-industrial period (between 1850 and 1900) due to human activities, primarily fossil fuel burning, which increases heat-trapping greenhouse gas levels in Earth’s atmosphere.

- Global Warming Potential (GWP):

- The heat absorbed by any greenhouse gas in the atmosphere, as a multiple of the heat that would be absorbed by the same mass of carbon dioxide (CO2). GWP is 1 for CO2. For other gases it depends on the gas and the time frame.

- Carbon dioxide equivalent (CO2e or CO2eq or CO2-e) is calculated from GWP. For any gas, it is the mass of CO2 which would warm the earth as much as the mass of that gas. Thus it provides a common scale for measuring the climate effects of different gases. It is calculated as GWP times mass of the other gas. For example, if a gas has GWP of 100, two tonnes of the gas have CO2e of 200 tonnes.

- GWP was developed to allow comparisons of the global warming impacts of different gases.

- Greenhouse Gas (GHG):

- A greenhouse gas is any gaseous compound in the atmosphere that is capable of absorbing infrared radiation, thereby trapping and holding heat in the atmosphere. By increasing the heat in the atmosphere, greenhouse gases are responsible for the greenhouse effect, which ultimately leads to global warming.

- The main gases responsible for the greenhouse effect include carbon dioxide, methane, nitrous oxide, and water vapor (which all occur naturally), and fluorinated gases (which are synthetic).

- GHG Protocol Corporate Standard Scope 1, 2 and 3: https://ghgprotocol.org/ + The GHG Protocol Corporate Accounting and Reporting Standard provides requirements and guidance for companies and other organizations preparing a corporate-level GHG emissions inventory. Scope 1 and 2 are mandatory to report, whereas scope 3 is voluntary and the hardest to monitor.

- Scope 1: Direct emissions:

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Stationary combustion (e.g fuels, heating sources). All fuels that produce GHG emissions must be included in scope 1.

- Mobile combustion is all vehicles owned or controlled by a firm, burning fuel (e.g. cars, vans, trucks). The increasing use of “electric” vehicles (EVs), means that some of the organisation fleets could fall into Scope 2 emissions.

- Fugitive emissions are leaks from greenhouse gases (e.g. refrigeration, air conditioning units). It is important to note that refrigerant gases are a thousand times more dangerous than CO2 emissions. Companies are encouraged to report these emissions.

- Process emissions are released during industrial processes, and on-site manufacturing (e.g. production of CO2 during cement manufacturing, factory fumes, chemicals).

- Direct emissions from company-owned and controlled resources. In other words, emissions are released into the atmosphere as a direct result of a set of activities, at a firm level. It is divided into four categories:

- Scope 2: Indirect emissions – owned:

- Indirect emissions from the generation of purchased energy, from a utility provider. In other words, all GHG emissions released in the atmosphere, from the consumption of purchased electricity, steam, heat and cooling. For most organisations, electricity will be the unique source of scope 2 emissions. Simply stated, the energy consumed falls into two scopes: Scope 2 covers the electricity consumed by the end-user. Scope 3 covers the energy used by the utilities during transmission and distribution (T&D losses).

- Scope 3: Indirect emissions – not owned:

- Indirect emissions – not included in scope 2 – that occur in the value chain of the reporting company, including both upstream and downstream emissions. In other words, emissions are linked to the company’s operations. According to GHG protocol, scope 3 emissions are separated into 15 categories.

- Scope 1: Direct emissions: