Eaton – Eaton’s battery configuration switch provides EV charging flexibility

SOUTHFIELD, Mich. – Intelligent power management company Eaton today announced it has partnered with Munich Electrification to develop and market its battery configuration switch (BCS), an advanced solution for 400-volt/800-volt dual string battery packs in electrified vehicles.

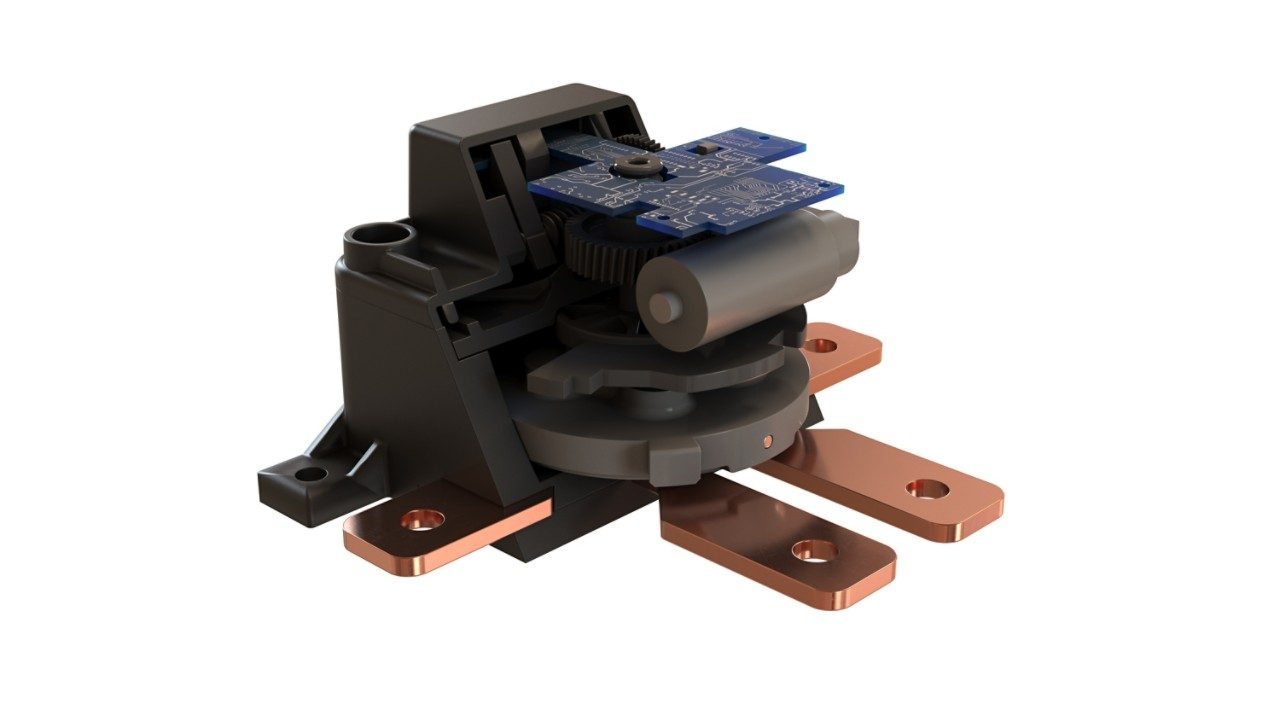

This innovative, integrated, bi-stable device for parallel/series reconfiguration allows 800-volt vehicles to effectively charge via a 400-volt charger, while also offering numerous benefits compared to traditional solutions.

“At Eaton, we’re leveraging our extensive background in developing electrified mobility solutions to launch this promising new technology in partnership with Munich Electrification, which specializes in developing cutting-edge battery management systems. There are a lot of 800-volt vehicles in the market, but many charging stations can only supply 400-volt power. BCS provides charging flexibility to consumers who want access to an expanded network of DC chargers.”

Mark Schneider, President, Eaton’s eMobility

Designed for automotive, light commercial and UTV applications, Eaton’s BCS enables the reduction of up to 12 components in a battery disconnect unit, simplifying the system and streamlining packaging and assembly. Furthermore, the BCS minimizes contact resistance, enhancing overall system efficiency and performance by reducing the number of contact points required by conventional contactors.

Ensuring higher EV safety standards, the BCS has a mechanical interlock that prevents pack short circuits due to crashes, software bugs, or contactor malfunctions. The BCS can also maintain stable conditions when the electronic control unit loses power. Its bi-stable nature enhances efficiency during normal operations by eliminating the hold current of a traditional contactor, and also provides resilience against low voltage faults by maintaining a safe condition for a wide range of potential failure modes.

“We are thrilled to collaborate with Eaton in launching this groundbreaking new technology developed by our outstanding R&D team. Munich Electrification’s legacy of innovation in the EV battery industry combined with Eaton’s expertise in electrical switching and automotive manufacturing is helping us to solve our customers’ biggest challenges together. ”

Uwe Wiedemann, Managing Director, Munich Electrification

Learn about Eaton’s BCS technology and other vehicle electrification solutions.

SourceEaton

EMR Analysis

More information on Eaton: See full profile on EMR Executive Services

More information on Craig Arnold (Chairman and Chief Executive Officer, Eaton): See full profile on EMR Executive Services

More information on Eaton Mobility Group: No specific website available yet + Eaton’s Mobility Group (previously named separately Eaton Vehicle Business and Eaton E-Mobility Business) represents the company’s focus on providing solutions across the propulsion spectrum and meeting the evolving needs of its customers from internal combustion to electrified or a combination of both.

To support increasing degrees of electrification, the Mobility Group offers a suite of technologies, including power distribution solutions, power electronics and transmissions that improve safety, efficiency, and performance.

Power connection solutions were introduced following the acquisition in 2022 of Royal Power Solutions, a global leader in the development and production of critical high-precision power- and signal-distribution components.

The principal markets for the Mobility Group are original equipment manufacturers of on- and off-highway vehicles and aftermarket customers.

More information on Peter Denk (Leadership Team – President, Mobility Group, Eaton): See full profile on EMR Executive Services

More information on Eaton eMobility Business: https://www.eaton.com/us/en-us/products/emobility/expertise.html?wtredirect=www.eaton.com/eMobility + Eaton’s eMobility business was formed by combining products, expertise and global manufacturing capabilities from Eaton’s Electrical and Vehicle Groups. Eaton plans to further develop new products and technologies, including smart diagnostics, intelligent power electronics and predictive health monitoring systems, to strengthen its global capabilities and deliver intelligent electrification solutions to passenger car, commercial vehicle and off-highway customers.

The principal markets for the Mobility Group are original equipment manufacturers of on- and off-highway vehicles and aftermarket customers.

More information on Mark Schneider (President, eMobility Business, Eaton): See full profile on EMR Executive Services

More information on Munich Electrification: https://www.munichelectrification.com/about + We develop innovative electronic control units for electric vehicles for our global customers. Our battery management system is world-leading regarding safety, features and costs. Our products stand out for function-integration, scalability, variant handling, space and weight. They are being used worldwide in multiple series production vehicles. Combining Silicon Valley’s spirit, pace and ambition with German engineering excellence, we strive to be a distinctive lead supplier for the electrified automotive world and beyond. Our international team is composed of highly motivated and exceptional employees. We offer a relaxed and friendly work atmosphere with flat hierarchies. As a small and specialized team we are well-aware of the importance of each individual colleague and support and promote each employee according to their abilities and needs. Our office with adjacent prototype and testing lab is located in the heart of Munich close to Heimeranplatz.

More information on Georg-Friedrich Graf (Chief Executive Officer, Munich Electrification): https://www.munichelectrification.com/about + https://www.linkedin.com/in/gfgraf/

More information on Uwe Wiedemann (Managing Director and Chief Growth Officer, Munich Electrification): https://www.munichelectrification.com/about + https://www.linkedin.com/in/uwewiedemann/

EMR Additional Notes:

- Battery Configuration Switch (BCS):

- A Battery Configuration Switch (BCS) is a device that allows for flexible charging options in electric vehicles (EVs) equipped with dual-string battery packs. It enables these EVs to charge efficiently using both 400-volt and 800-volt chargers, expanding charging accessibility and convenience.

- AC (Alternating Current) & DC (Direct Current) & UC (Universal Current):

- Direct current (DC) is an electric current that is uni-directional, so the flow of charge is always in the same direction. As opposed to alternating current, the direction and amperage of direct currents do not change. It is used in many household electronics and in all devices that use batteries.

- Direct current has many uses, from the charging of batteries to large power supplies for electronic systems, motors, and more. Very large quantities of electrical energy provided via direct-current are used in smelting of aluminum and other electrochemical processes.

- in contrast to AC power, DC power is entirely made up of active power, meaning that there are almost no losses due to the capacitance of wires when DC power travels long distances. In fact, high voltage AC transmission systems have losses of 7% to 15% with aboveground transmission.

- Alternating Current is used in homes as Direct current can not be easily stepped up or stepped down with the help of transformers whereas alternating current can easily be converted from low voltage to high voltage or vice-versa with the help of transformers.

- “UC” is used for “Universal Current”, that translates to “either DC or AC”. So a 24 V UC input can accept either 24 V AC or 24 V DC.

- Utility Task / Terrain Vehicle (UTV):

- Vehicles that are built and used more for work than recreation. They are large, powerful, able to seat passengers side by side, and built with lots of storage space. They’re commonly used to haul equipment and supplies in locations that make using a truck impractical or impossible.

- All Terrain Vehicle (ATV):

- Motorized off-highway vehicle designed to travel on four low-pressure or non-pneumatic tires, having a seat designed to be straddled by the operator and handlebars for steering control.

- The UTV often features a roll cage, with some also sporting a roof. Unlike an ATV, which is controlled more like a motorcycle, UTVs are operated like a car, using a steering wheel and foot pedals. Most UTVs also are equipped with seatbelts, which ATVs do not have.

- Contactor:

- A contactor is an electrical device that is widely used for switching circuits on and off. As such, electrical contactors form a subcategory of electromagnetic switches known as relays. A relay is an electrically operated switching device that uses an electromagnetic coil to open and close a set of contacts.

- A safety contactor has the same functionality and purpose as a standard contactor except that the contacts are mechanically linked together so all three poles will close together and fail in an open state. This means that if a safety contactor fails, the control voltage will be applied but the contacts will not close.

- Contactors are typically built for and used in 3-phase applications where a relay is more commonly used in single phase applications. A contactor joins 2 poles together, without a common circuit between them, while a relay has a common contact that connects to a neutral position.

- We use a contactor to turn on and off heavy and high voltage electrical devices such as motors, fans, pumps, etc.