Emerson – New IO-Link Master Reduces Hardware Costs, Future-Proofs Pneumatic Valve Systems with IIoT Integration

Customers can reduce costs by including multiple IO-Link masters on one G3 Fieldbus platform

NOVI, Mich. (Aug. 31, 2023) – Emerson has introduced a new Class A, IO-Link master that provides customers with a cost-effective solution for smart and analog sensor connectivity on the AVENTICS™ Series G3 Fieldbus platform. The G3 IO-Link Master is suitable for machine architectures with many sensors and pneumatic valves, and where it’s important to have reliable digital data communication between field devices, such as sensors and the machine controller. Application areas include automotive, tire manufacturing, food and beverage, packaging and metalworking.

IO-Link is an internationally standardized I/O technology (IEC 61131-9) for communication at the sensor/actuator level in machine control. During replacement, IO-Link devices can identify and configure themselves automatically, saving maintenance time. The IO-Link master provides pneumatic valve control through direct digital data communication with the machine controller. It offers event-based and I/O mapped diagnostics – both important predictive maintenance requirements for Industry 4.0 and Industrial Internet of Things (IIoT) applications.

By adding the IO-Link capabilities to our valve systems, our customers can include multiple IO-Link masters on only one G3 Fieldbus platform, saving hardware costs, thus enabling our customers to be future-proof and positioned for Industry 4.0/IIoT application requirements.

Customers can cut costs by reducing the number of communication nodes. G3 IO-Link master is optimized for sensor-rich applications with eight Class A ports per module to support multiple IO-Link smart and standard analog sensors. The IO-Link master can be distributed up to 30 meters away from G3. Together with the 20-meter IO-Link cable length maximum, the sensors can be located up to 50 total meters in total from the G3 Fieldbus platform. As a result, material cost is reduced, and machines are more streamlined because fewer cables are required.

The IO-Link Master offers a complete Emerson solution. Customers can experience the benefits of integrating IIoT into their systems by connecting to the IO-Link-capable Series AV03/AV05 and 500 valve systems, Series EV12 and EV18 electropneumatic pressure regulators, Series 617 Sentronic LP and Series 614 Sentronic PLUS proportional valves, Series ECD-IV and ECD-LV intelligent compact vacuum ejectors, Series SM6-AL distance measuring sensors, Series ST4-2P magnetic proximity sensors, Series PE5 and PE7 pressure sensors, and Series AF2 flow sensors. In addition, Class B IO-Link solutions can be supported with an optional T-adapter.

The G3 is the only fieldbus electronics platform for pneumatic valve systems that contains a graphical display used for configuration, commissioning, and diagnostics. It offers improvements in performance and reduces maintenance for original equipment manufacturers (OEMs) and end-users alike. The G3 IO-Link Master can also be configurable with the G3 web server. With easy access to connections, the electronic platform is simple to assemble, install, commission, and maintain. G3’s functionality allows programmable logic controllers to efficiently turn valves on and off, and to channel I/O data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks.

Further benefits include compatibility with the full G3 range of valve interfaces, including Series 501, 502, 503 (ISO15407-2), 2035, 2002, 2005, 2012 and 511, 512, 513 (ISO 5599-2). The G3 IO-Link Master supports the widely used protocols EtherNet/IP™ DLR and PROFINET™. Additional protocols are available upon request.

For more information, visit Emerson.com/en-us/catalog/aventics-g3.

SourceEmerson

EMR Analysis

More information on Emerson: See the full profile on EMR Executive Services

More information on Lal Karsanbhai (President and Chief Executive Officer, Emerson): See the full profile on EMR Executive Services

More information on AVENTICS™ Series SPRA Electric Rod-Style Actuators by Emerson: https://www.emerson.com/en-us/catalog/aventics-spra?fetchFacets=true#facet:&partsFacet:&modelsFacet:&facetLimit:&searchTerm:&partsSearchTerm:&modelsSearchTerm:&productBeginIndex:0&partsBeginIndex:0&modelsBeginIndex:0&orderBy:0&partsOrderBy:&modelsOrderBy:&pageView:list&minPrice:&maxPrice:&pageSize:&facetRange:& + The AVENTICS Series SPRA electric rod-style actuators are the ideal solution to perform fast and powerful linear movements. They are very flexible, precise and energy efficient, improving sustainability and Total Cost of Ownership (TCO). The modular concept of the Series SPRA enables easy connection to your preferred motor and control system, saving you time and costs on design and programming. The Series SPRA is ISO 15552 compliant and uses high-grade materials – such as a IP54S sealing system, ensuring a high level of reliability even in harsh conditions.

More information on G3 IO-Link Master by Emerson: https://www.emerson.com/en-us/catalog/automation-solutions/aventics-g3 + In today’s highly automated machines, the AVENTICS Series G3 electronic fieldbus valve system is replacing conventional hardwired solutions. It integrates communication interfaces to pneumatic valve systems with input/output (I/O) capabilities. This next-generation electronic platform permits easy access to connections; it’s simple to assemble, install, commission, and maintain. The G3’s functionality allows programmable logic controllers to more efficiently turn valves on and off, and to channel I/O data from sensors, lights, relays, individual valves, or other I/O devices via various industrial networks including IO-Link devices via the IO-Link Class A Master. The G3 is the only pneumatic valve manifold that contains a graphical display used for configuration, commissioning, and diagnostics. It offers improvements in application, performance, and maintenance for original equipment manufacturers (OEMs) and end users alike.

More information on International Electrotechnical Commission (IEC): https://www.iec.ch/homepage + The IEC is a global, not-for-profit membership organization, whose work underpins quality infrastructure and international trade in electrical and electronic goods. Our work facilitates technical innovation, affordable infrastructure development, efficient and sustainable energy access, smart urbanization and transportation systems, climate change mitigation, and increases the safety of people and the environment.

The IEC brings together more than 170 countries and provides a global, neutral and independent standardization platform to 20 000 experts globally. It administers 4 Conformity assessment systems whose members certify that devices, systems, installations, services and people work as required.

The IEC publishes around 10 000 IEC International Standards which together with conformity assessment provide the technical framework that allows governments to build national quality infrastructure and companies of all sizes to buy and sell consistently safe and reliable products in most countries of the world. IEC International Standards serve as the basis for risk and quality management and are used in testing and certification to verify that manufacturer promises are kept.

IEC work directly underpins the targets of all 17 UN Sustainable Development Goals.

More information on Yinbiao Shu (President, International Electrotechnical Commission (IEC)): https://www.iec.ch/basecamp/yinbiao-shu

More information on ISO: http://www.iso.org/ + ISO (International Organization for Standardization) is the world’s largest developer of International Standards. Through our members and their stakeholders, we bring people together to create International Standards that respond to global challenges. ISO standards support global trade, drive inclusive and equitable economic growth, advance innovation and promote health and safety to achieve a sustainable future. Follow us to learn more about standards and how you can participate to making lives easier, safer, and better.

EMR Additional Notes:

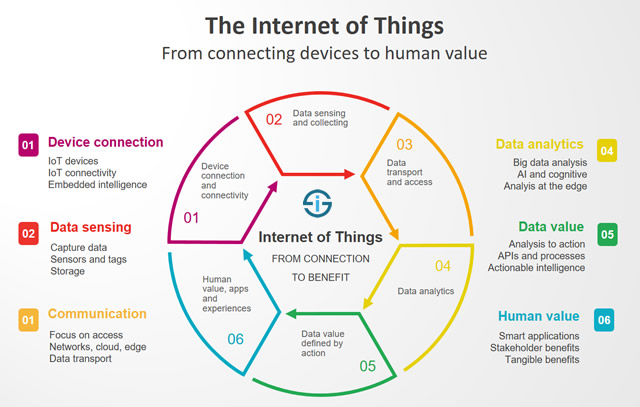

- IOT (The Internet Of Things):

- The Internet of Things (IoT) refers to a system of interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

- Describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

- The Most Popular IoT Devices are:

- Smart watches are the most popular IoT devices. …

- Gaming consoles. …

- Smart TV sets and content streaming devices. …

- Voice control devices. …

- Printers. …

- Cameras. …

- Lighting appliances. …

- Smart thermostats.

- Industrial IoT Solutions:

- Industrial IoT (IIoT) involves collecting and analyzing sensor-generated data to support equipment monitoring and maintenance, production process analytics and control, and more. In manufacturing IT since 1989, ScienceSoft offers IIoT consulting and development to create secure IIoT solutions.

- IT & OT:

- Information technology (IT) refers to anything related to computer technology, including hardware and software. Your email, for example, falls under the IT umbrella. This form of technology is less common in industrial settings, but often constitutes the technological backbone of most organizations and companies. These devices and programs have little autonomy and are updated frequently.

- Operational technology (OT) refers to the hardware and software used to change, monitor, or control physical devices, processes, and events within a company or organization. This form of technology is most commonly used in industrial settings, and the devices this technology refers to typically have more autonomy than information technology devices or programs. Examples of OT include SCADA (Supervisory Control and Data Acquisition).

- => The main difference between OT and IT devices is that OT devices control the physical world, while IT systems manage data.

- IO-Link:

- IO-Link is a powerful standard, an increasingly deployed point-to-point serial communication protocol.

- It allows for the bi-directional exchange of data and is used to communicate with sensors and/or actuators.

- Extending the globally recognized PLC standard IEC 61131, it allows three types of data to be exchanged – Process data, service data, and events.

- Major sensor manufacturers and industrial manufacturing companies have joined the international IO-Link Consortium to promote the IO-Link communication protocol due to its many advantages over standard I/O.

- I/O:

- Input/output

- Describes any operation, program, or device that transfers data to or from a computer. Typical I/O devices are printers, hard disks, keyboards, and mouses.

- Fieldbus Protocol:

- Fieldbus refers to a collection of industrial computer networks that allows input devices such as Ethernet switches and sensors to communicate with output devices such as valves and drives without having to connect every single device back to a controller.

- Basically, Fieldbus works on a network that permits various topologies such as the ring, branch, star, and daisy chain. Prior to Fieldbus protocols, industrial controller systems were connected using RS232 serial communications. As you know, serial communications allowed only two devices to communicate.

- Profinet and Profibus: https://www.profibus.com/ + https://www.profibus.com/technology/profinet

- PROFINET has become the leading Industrial Ethernet Standard in the market. This globally established and future-oriented technology is supported by many product vendors, thus ensuring long-term availability and investment protection.

- PROFIBUS & PROFINET International (PI) is the most influential interest group in the field of industrial communication. We network expertise, companies and people – regionally and internationally. Through our member companies working closely together ideas will become standards, standards will lead to innovative products, and innovative products will deliver powerful automation solutions for the future.

- Standard Ethernet is only suitable for data transmission in home, office, and select industrial-monitoring settings. In contrast, the industrial Ethernet of PROFINET is suitable for installation in harsh industrial facilities requiring deterministic data communications.

- PROFIBUS is a classic serial Fieldbus, and PROFINET is an industrial Ethernet protocol. PROFIBUS and PROFINET are both IEC standards created by the same organization: PROFIBUS and PROFINET International. Because of their common source, PROFIBUS and PROFINET do share some similarities. But generally, they are very different. Everything started with PROFIBUS, introduced in 1989, and grew rapidly in the 90s. Then, as the industry shifted from fieldbuses to Industrial Ethernet, PI developed PROFINET, which became available in the early 2000s, and has grown rapidly ever since.

- PROFIBUS networks are generally characterized by purple single-pair RS-485 cabling. And those cables use the standard DB9 or M12 connectors. PROFINET networks, on the other hand, typically use green industrially graded Ethernet cables. For PROFINET networks, the most common connector type is RJ45, but M12 connectors are also used in high exposure environments and BFOCs for fiber optic applications.

- Because it’s ethernet based, PROFINET can operate on a much higher transmission speed than PROFIBUS. With PROFINET, the cycle times are also adjustable for each device, whereas PROFIBUS has a fixed cycle time. PROFINET is applied in a wide variety of industries, such as automotive, oil and gas, logistics, etc.

- Profibus is also a master-slave type protocol like Modbus but with an additional token ring protocol to allow for multiple masters. Also, unlike Modbus, all devices go through a startup sequence during which they “join” the network. Each slave maintains a failsafe timer.

- Industry 4.0:

- Industry 4.0 has been defined as “a name for the current trend of automation and data exchange in manufacturing technologies, including cyber-physical systems, the Internet of things, cloud computing and cognitive computing and creating the smart factory”

- Industry 4.0 aims at transforming the manufacturing and engineering sectors by introducing factories where cyber-processing systems communicate over the Internet of Things, assisting people and machinery to execute their tasks within the shortest time possible.

- Industry 4.0 technology helps you manage and optimize all aspects of your manufacturing processes and supply chain. It gives you access to the real-time data and insights you need to make smarter, faster decisions about your business, which can ultimately boost the efficiency and profitability of your entire operation.

- The Fourth Industrial Revolution (4IR) is a term coined in 2016 by Klaus Schwab, Founder and Executive Chairman of the World Economic Forum (WEF).

- 4 Industrial Revolutions:

- First Industrial Revolution: Coal in 1765.

- Second Industrial Revolution: Gas in 1870.

- Third Industrial Revolution: Electronics and Nuclear in 1969.

- Fourth Industrial Revolution: Internet and Renewable Energy in 2000.

- The Fifth Industrial Revolution, or 5IR, encompasses the notion of harmonious human–machine collaborations, with a specific focus on the well-being of the multiple stakeholders (i.e., society, companies, employees, customers)

- OEM (Original Equipment Manufacturer):

- Company that produces parts and equipment that may be marketed by another manufacturer.

- Usually tagged on hardware or software that’s less expensive than normal retail products.

- An OEM refers to something made specifically for the original product, while the aftermarket refers to equipment made by another company that a consumer may use as a replacement.

- Electrical OEM manufacturers makes equipment or components that are then utilized by its customer, another manufacturer or a reseller, usually under the final reseller’s brand name. OEMs come in many shapes and sizes, making complete devices or specific components.

- MRO (Maintenance, Repair and Operations):

- It refers to all the activities needed to keep a company’s facilities and production processes running smoothly.

- Supplies consumed in the production process that do not become part of the end product.

- Maintenance professionals use MRO items to maintain company structures, equipment, and assets. Purchases that fall under MRO include maintenance tools and equipment, replacement parts for production equipment, consumables such as personal protective equipment (e.g., safety goggles, work gloves), cleaning products and office supplies.

- Integrated Supply:

- Integrated supply chain management refers to an enterprise resource planning approach to supply chain management.

- Large-scale business strategy that brings as many links of the chain as possible into a closer working relationship with each other. The goal is to improve response time, production time, and reduce costs and waste.

- Often takes the form of integrated computer systems. For example, the supplier’s computer system may be set up to deliver real-time data to the buyer’s computer. This allows the buyer to know: The current status of all orders., which products are in the supplier’s inventory …

- Integration, operations, purchasing and distribution are the four elements of the supply chain that work together to establish a path to competition that is both cost-effective and competitive.

- Integrated supply is the end-to-end process of managing the MRO supply chain (spare parts) through consolidated sourcing practices, storeroom operations, inventory management, data governance, and continuous improvement. The objective is to leverage spend, reduce transactions, and cut inventory and associated costs while eliminating risk around critical spares.

- EtherCAT:

- The Ethernet Fieldbus: https://www.ethercat.org/default.htm + EtherCAT is the open real-time Ethernet network originally developed by Beckhoff. EtherCAT sets new standards for real-time performance and topology flexibility.

- EtherCAT Technology Group:

- The worlds largest Industrial Ethernet organization with 6900 member companies: https://www.ethercat.org/en/tech_group.html + The ETG is a global organization in which OEM, End Users and Technology Providers join forces to support and promote the further technology development. The EtherCAT Technology Group keeps EtherCAT technology open for all potential users.

- Ethernet:

- Ethernet is a family of wired computer networking technologies commonly used in local area networks, metropolitan area networks and wide area networks. It was commercially introduced in 1980 and first standardized in 1983 as IEEE 802.3.

- Single Pair Ethernet (SPE):

- Single Pair Ethernet cables are copper cables that only contain one twisted pair (single pair) that they use for data transmission, for example in industrial applications.

- Describes the transmission of Ethernet over only one pair of twisted copper wires. In addition to data transmission via Ethernet, SPE also enables a simultaneous power supply of terminal devices via PoDL – Power over Data Line.

- As its name suggests, Single Pair Ethernet (SPE) cabling uses only one pair of wires to transmit data, as opposed to the two pair that have long been standard in the majority of Ethernet cabling in use worldwide.

- Single Pair Ethernet System Alliance:

- https://singlepairethernet.com/en/

- The Single Pair Ethernet System Alliance is a worldwide association of leading technology companies. We want to implement and further develop the pioneering Single Pair Ethernet technology. Together and holistically.

- The Single Pair Ethernet System Alliance is an ever-growing, collaborative community. Technology companies from all over the world jointly drive the further development of SPE technology and its implementation in various applications.

- Founding Members are: Weidmüller, Phoenix contact, Rosenberger, Datwyler, Draka and R&M

- PoE (Power over Ethernet):

- Power over Ethernet (PoE) is the process of sending electrical power and data over copper wire. The combination of data transmission along with power supplying hardware onto the same RJ45 Ethernet connector allows for the transmission of power over the network cabling.

- As PoE technology has developed, the amount of power that can be sent over Ethernet cable has increased. IEEE-compliant PoE switches and injectors can output anywhere from 12 watts to over 70 watts of power per port.