Honeywell – Honeywell To Acquire Sundyne To Expand Critical Equipment Portfolio and Aftermarket Services

- Honeywell’s strategic growth will be bolstered by the addition of Sundyne’s differentiated products that address the increasing global need for energy security

- Sundyne’s installed base across refining and petrochemicals, liquefied natural gas and clean and renewable fuels will expand the capabilities of Honeywell’s Energy and Sustainability Solutions business segment

- Combination will enhance Honeywell’s end-to-end solutions in process technologies and critical equipment, alongside automation and control systems enabled by Honeywell Forge

- Honeywell’s global footprint and customer relationships will also expand the available market for Sundyne’s unique offerings and services

- Acquisition is expected to be immediately accretive to Honeywell’s sales growth and segment margins, as well as to adjusted EPS in the first full year of ownership

CHARLOTTE, N.C., March 4, 2025 /PRNewswire/ — Honeywell (NASDAQ: HON) today announced that it has agreed to acquire Sundyne from private equity firm Warburg Pincus for $2.16 billion in an all-cash transaction. This represents approximately 14.5x 2024 EBITDA on a tax-adjusted basis. Sundyne is a leader in the design, manufacturing and aftermarket support of highly-engineered pumps and gas compressors used in process industries. The addition of Sundyne’s differentiated equipment will enhance the ability of Honeywell’s Energy and Sustainability Solutions (ESS) business segment to drive innovation and efficiency, while supporting critical energy security needs across the world.

Sundyne’s deep customer relationships, best-in-class products and technology will unlock strategic growth potential for Honeywell UOP’s value chains in refining and petrochemicals, liquefied natural gas (LNG) and clean and renewable fuels. The combination will result in an improved product offering for customers as Honeywell Forge, a leading IoT platform, will enable the digitalization of Sundyne’s equipment to enhance reliability and predictive maintenance. Utilizing Honeywell’s advanced R&D capabilities, the combined company will also be able to further accelerate new product development in the pumps and compressors space.

“By combining Honeywell’s top-tier technology with Sundyne’s leading process industry solutions, this acquisition will further enhance our dynamic Honeywell UOP business and create strategic growth opportunities in attractive verticals,” said Vimal Kapur, Chairman and CEO of Honeywell. “Sundyne’s vast installed base of top-of-the-line pumps and compressors will further strengthen Honeywell’s brand in the process industry and create significant opportunities for us to continue expanding our aftermarket services business.”

Headquartered in Arvada, Colorado with additional locations around the globe, Sundyne brings approximately 1,000 skilled employees and a significant recurring aftermarket revenue generated from an extensive installed base. The integration is expected to generate material run-rate revenue synergies with Honeywell UOP process licensing and modular capabilities, as well as a global sales reach.

“Through the integration of Sundyne’s differentiated suite of products and equipment, combined with the process automation capabilities of our Honeywell Forge technology, we will be able to offer our customers a more comprehensive portfolio of solutions to meet their evolving needs,” said Ken West, President and CEO of Honeywell’s ESS segment.

“We are incredibly proud to have partnered with the talented leadership team at Sundyne over the past five years. Sundyne’s focus on diversifying its end markets, investing in innovative products, and optimizing its operations has set a solid foundation for sustained, above-market growth,” said Dan Zamlong, Managing Director, Warburg Pincus.

“The combination of Sundyne and Honeywell will add significant value for our customers, channel partners and employees—and we’re honored to join the Honeywell family,” said Sundyne’s CEO Mary Zappone. “There are numerous benefits that we can achieve together with Honeywell that will accelerate growth and improve efficiency for customers.”

The acquisition is expected to be immediately accretive to Honeywell’s sales growth and segment margin, as well as to adjusted EPS in the first full year of ownership.

The acquisition follows Honeywell’s recent announcement of the planned separation of its Aerospace Technologies business along with the previously announced spin of Advanced Materials, which will result in three publicly listed industry leaders with distinct strategies and growth drivers. Throughout the separation execution process, Honeywell intends to continue its portfolio transformation efforts to enhance the value proposition of its businesses.

Since December 2023, Honeywell has announced a number of strategic actions to drive organic growth and simplify its portfolio. This includes approximately $9 billion of accretive acquisitions: the Access Solutions business from Carrier Global, Civitanavi Systems, CAES Systems and the LNG business from Air Products. In addition, Honeywell entered into an agreement to divest its Personal Protective Equipment business, which is expected to close in the first half of 2025. Honeywell remains on pace to exceed its commitment to deploy at least $25 billion toward high-return capital expenditures, dividends, opportunistic share purchases and accretive acquisitions through 2025.

Honeywell’s acquisition of Sundyne is expected to close in Q2 2025, subject to customary closing conditions, including receipt of certain regulatory approvals.

SourceHoneywell

EMR Analysis

More information on Honeywell: See the full profile on EMR Executive Services

More information on Vimal Kapur (Chairman and Chief Executive Officer, Honeywell): See the full profile on EMR Executive Services

More information on Michal Stepniak (Senior Vice President and Chief Financial Officer, Honeywell): See the full profile on EMR Executive Services

More information on Honeywell Energy and Sustainability Solutions Segment (ESS) by Honeywell: https://ess.honeywell.com/us/en + With a decades-long focus on sustainability, Honeywell enables the energy evolution, improves resiliency and efficiency, reduces emissions, and facilitates the circular economy. Honeywell’s expertise in this area will continue helping solve the world’s toughest challenges across our end markets.

More information on Ken West (President and Chief Executive Officer, Energy and Sustainability Solutions Segment (ESS), Honeywell): See the full profile on EMR Executive Services

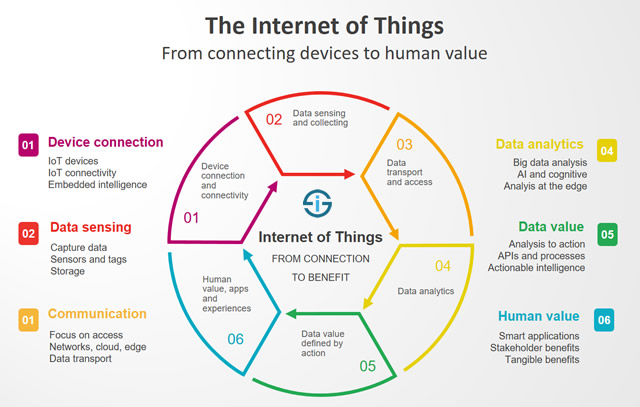

More information on Honeywell Connected Enterprise (HCE) + Honeywell Forge: https://www.honeywell.com/us/en/honeywell-forge + Honeywell Connected Enterprise (HCE) is transforming the way the world works, solving our customers’ toughest challenges through relentless innovation that is grounded in a heritage of invention. Honeywell founded HCE to develop Honeywell Forge, software that securely unites OT and IT data to make better decisions and improve operational performance. We help some of the world’s largest companies transform the way they work. Helping them become more sustainable, more efficient and more cybersecure.

More information on Forge by Honeywell: https://www.honeywell.com/us/en/honeywell-forge + Honeywell Forge is Enterprise Performance Management Software-as-a-Service, purpose-built on a native edge-to-cloud, data-driven architecture to accelerate digital transformation.

More information on Suresh Venkatarayalu (Senior Vice President, Chief Technology Officer and President, Honeywell Connected Enterprise, Honeywell): See the full profile on EMR Executive Services

More information on Honeywell UOP: https://uop.honeywell.com + Honeywell UOP is a leading international supplier and licensor of process technology, catalysts, adsorbents, equipment, and consulting services to the petroleum refining, petrochemical, and gas processing industries.

Honeywell UOP is part of Honeywell’s Performance Materials and Technologies strategic business group, which also includes Honeywell Process Solutions (www.honeywellprocess.com), a pioneer in automation control, instrumentation and services for the oil and gas, refining, petrochemical, chemical and other industries.

More information on Sundyne by Honeywell: https://www.sundyne.com/ + Sundyne is a leader in the design, manufacturing and aftermarket support of highly-engineered pumps and gas compressors used in process industries.

Sundyne is one of the few companies that design & manufacture both Pumps and Compressors. Through organic & inorganic growth, Sundyne has assembled industry-leading brands that provide customers with a wide range of fluid and gas handling services and solutions. Brands like Ansimag, HMD Kontro and Marelli have broadened the original Sundyne portfolio for a wider range of markets. Sundyne equipment can be built to most standards, including ANSI, ISO and API, and the line of Sunflo products offers non-standard solutions for a range of general industrial applications.

More information on Mary Zappone (Chief Executive Officer, Sundyne, Honeywell): See the full profile on EMR Executive Services

More information on Warburg Pincus: https://warburgpincus.com/ + Warburg Pincus LLC is the pioneer of global growth investing. A private partnership since 1966, the firm has the flexibility and experience to focus on helping investors and management teams achieve enduring success across market cycles. Today, the firm has more than $87 billion in assets under management, and more than 220 companies in their active portfolio, diversified across stages, sectors, and geographies. Warburg Pincus has invested in more than 1,000 companies across its private equity, real estate, and capital solutions strategies.

The firm is headquartered in New York with offices in Amsterdam, Beijing, Berlin, Hong Kong, Houston, London, Luxembourg, Mumbai, Mauritius, San Francisco, São Paulo, Shanghai, and Singapore.

More information on Charles R. Kaye (Chairman, Warburg Pincus): https://warburgpincus.com/team/

More information on Jeffrey Perlman (Chief Executive Officer, Warburg Pincus): https://warburgpincus.com/team/ + https://warburgpincus.com/2024/07/17/warburg-pincus-names-jeffrey-perlman-chief-executive-officer/ + https://www.linkedin.com/in/jeffrey-perlman-9055b020/

More information on Dan Zamlong (Managing Director, Investment Staff, Industrials, NewYork, Warburg Pincus): https://warburgpincus.com/team/ + https://www.linkedin.com/in/daniel-zamlong-39580414a/

EMR Additional Notes:

- Pumps and Compressors:

- A pump moves an incompressible fluid (e.g., liquid) whose volume does not (significantly) change with pressure and temperature.

- A compressor moves a compressible fluid (e.g., gas) whose volume is strongly influenced by pressure and temperature.

- Propane or Liquefied Petroleum Gas (“LPG”):

- Colourless, easily liquefied, gaseous hydrocarbon (compound of carbon and hydrogen), the third member of the paraffin series following methane and ethane. The chemical formula for propane is C3H8. It is separated in large quantities from natural gas, light crude oil, and oil-refinery gases and is commercially available as liquefied propane or as a major constituent of liquefied petroleum gas (LPG).

- LPG is a broader term that encompasses a mixture of hydrocarbon gases. Propane is the most common component of LPG (Other components of LPG may include butane, isobutane, and small amounts of other hydrocarbons). So, while all propane is considered LPG, not all LPG is solely propane.

- Isobutane:

- Isobutane, also known as i-butane, 2-methylpropane or methylpropane, is a chemical compound with molecular formula HC(CH3)3. It is an isomer of butane. Isobutane is a colorless, odorless gas. It is the simplest alkane with a tertiary carbon atom.

- Propane vs. Isobutane: Propane is more widely used as a fuel for heating, cooking, and vehicles due to its lower cost and wider availability while Isobutane is commonly used as a refrigerant in air conditioning systems and as a propellant in aerosol cans. It is also used in some types of lighter fluid.

- Liquefied Natural Gas (“LNG”):

- LNG fuel, or liquefied natural gas, is a natural gas converted to liquid form through liquefaction. During this process, natural gas is cooled at low temperatures until it turns into a liquid, and the volume of gas is reduced by approximately 600 times.

- When LNG is returned to its gaseous state, it is used across the residential, commercial and industrial sectors for purposes as diverse as heating, cooking, generating electricity and manufacturing a wide variety of products. LNG is also used as a fuel for heavy-duty and other vehicles.

- Differences between LNG & LPG (Also known as propane or butane):

- Light pressure is used to liquefy LPG, while LNG is liquefied cryogenically, i.e. through exposure to extremely low temperatures

- LPG is stored, shipped and transported in tanks or cylinders, whereas LNG is stored and shipped in purpose built cryogenic tanks. Pipelines are usually used to transport LNG.

- The need for cryogenic storage, coupled with infrastructure requirements such as production plants, dispensing stations and pipeline transport facilities, means LNG is not a viable option in many developing nations.

- Earning Per Share (EPS):

- Company’s net income subtracted by preferred dividends and then divided by the average number of common shares outstanding. The resulting number serves as an indicator of a company’s profitability. It is common for a company to report EPS that is adjusted for extraordinary items and potential share dilution.

- The higher a company’s EPS, the more profitable it is considered to be.

- Earnings per share value is calculated as net income (also known as profits or earnings) divided by available shares. A more refined calculation adjusts the numerator and denominator for shares that could be created through options, convertible debt, or warrants. The numerator of the equation is also more relevant if it is adjusted for continuing operations.

- EBITA:

- Earnings before interest, taxes, and amortization (EBITA) is a measure of company profitability used by investors. It is helpful for comparing one company to another in the same line of business.

- EBITA = Net income + Interest + Taxes + Amortization

- EBITDA:

- Earnings before interest, taxes, depreciation, and amortization (EBITDA) is an alternate measure of profitability to net income. By including depreciation and amortization as well as taxes and debt payment costs, EBITDA attempts to represent the cash profit generated by the company’s operations.

- EBITDA and EBITA are both measures of profitability. The difference is that EBITDA also excludes depreciation.

- EBITDA is the more commonly used measure because it adds depreciation—the accounting practice of recording the reduced value of a company’s tangible assets over time—to the list of factors.

- EV/EBITDA (Enterprise Multiple):

- Enterprise multiple, also known as the EV-to-EBITDA multiple, is a ratio used to determine the value of a company.

- It is computed by dividing enterprise value by EBITDA.

- The enterprise multiple takes into account a company’s debt and cash levels in addition to its stock price and relates that value to the firm’s cash profitability.

- Enterprise multiples can vary depending on the industry.

- Higher enterprise multiples are expected in high-growth industries and lower multiples in industries with slow growth.

- IoT (Internet of Things):

- The Internet of Things (IoT) refers to a system of interrelated, internet-connected objects that are able to collect and transfer data over a wireless network without human intervention.

- Describes the network of physical objects—“things”—that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

- The Most Popular IoT Devices are:

- Smart watches are the most popular IoT devices. …

- Gaming consoles. …

- Smart TV sets and content streaming devices. …

- Voice control devices. …

- Printers. …

- Cameras. …

- Lighting appliances. …

- Smart thermostats.

- IIoT (Industrial IoT):

- Industrial IoT (IIoT) involves collecting and analyzing sensor-generated data to support equipment monitoring and maintenance, production process analytics and control, and more. In manufacturing IT since 1989, ScienceSoft offers IIoT consulting and development to create secure IIoT solutions.

- AIoT (Artificial Intelligence of Things):

- Relatively new term and has recently become a hot topic which combines two of the hottest acronyms, AI (Artificial Intelligence) and IoT (Internet of Things).

- AIoT is transformational and reciprocally beneficial for both types of technology, as AI adds value to IoT through machine learning capabilities and improved decision-making processes, while IoT adds value to AI through connectivity, signalling, and data exchange.

- Aim: achieve more efficient IoT operations, improve human-machine interactions and enhance data management and analytics.

- xIoT (xTended Internet of Things):

- xIoT refers to the “xTended” Internet of Things. This xTended IoT category spans Enterprise IoT devices (cameras, printers, and door controllers), OT devices (like PLCs, HMI’s, and robotics) and Network devices (like switches, WiFi routers, and NAS).

- Industrial Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Fixed Automation:

- Fixed automation systems are utilized in high volume production settings that have dedicated equipment. The equipment has fixed operation sets and is designed to perform efficiently with the operation sets. This type of automation is mainly used in discrete mass production and continuous flow systems like paint shops, distillation processes, transfer lines and conveyors. All these processes rely on mechanized machinery to perform their fixed and repetitive operations to achieve high production volumes.

- Programmable Automation:

- Programmable automation systems facilitate changeable operation sequences and machine configuration using electronic controls. With programmable automation, non-trivial programming efforts are required to reprogram sequence and machine operations. Since production processes are not changed often, programmable automation systems tend to be less expensive in the long run. This type of system is mainly used in low job variety and medium-to-high product volume settings. It may also be used in mass production settings like paper mills and steel rolling mills.

- Flexible Automation:

- Flexible automation systems are utilized in computer-controlled flexible manufacturing systems. Human operators enter high-level commands in the form of computer codes that identify products and their location in the system’s sequence to trigger automatic lower-level changes. Every production machine receives instructions from a human-operated computer. The instructions trigger the loading and unloading of necessary tools before carrying out their computer-instructed processes. Once processing is completed, the end products are transferred to the next machine automatically. Flexible industrial automation is used in batch processes and job shops with high product varieties and low-to-medium job volumes.

- Integrated Automation:

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Computer-aided process planning

- Computer-supported design and manufacturing

- Flexible machine systems

- Computer numerical control machine tools

- Automated material handling systems, like robots

- Automatic storage and retrieval systems

- Computerized production and scheduling control

- Automated conveyors and cranes

- Additionally, an integrated automation system can integrate a business system via a common database. That is, it supports the full integration of management operations and processes using communication and information technologies. Such technologies are utilized in computer integrated manufacturing and advanced process automation systems.

- Integrated industrial automation involves the total automation of manufacturing plants where all processes function under digital information processing coordination and computer control. It comprises technologies like:

- Fixed Automation:

- Industrial automation is the use of technologies such as computer software and robotics to control machinery and processes which replace human beings in performing specific functions. The functions are primarily centered on manufacturing, quality control and material handling processes.

- Process Automation / Manufacturing:

- Process automation is defined as the use of software and technologies to automate business processes and functions in order to accomplish defined organizational goals, such as producing a product, hiring and onboarding an employee, or providing customer service.

- Process manufacturing utilizes chemical, physical and compositional changes to convert raw material or feedstock into a product. Process manufacturing includes industries such as cement and glass, chemicals, electric power generation, food and beverage, life sciences, metals and mining, oil and gas, pulp and paper, refining, and water and wastewater. Process manufacturing includes both continuous and batch processes.

- Discrete Automation / Manufacturing:

- Discrete automation is the production of parts that are of a quantifiable nature. That may include cell phones, soda bottles, automobiles, airplanes, toys, etc. As you know, an automobile contains many, many parts. The parts required for an automobile are also quantifiable in nature.

- Discrete manufacturing processes include the production of individual parts as well as their assembly into a final product. Discrete manufacturing examples include automobiles, appliances, and consumer electronics.

- Hybrid Automation / Manufacturing:

- The Hybrid Automation Method follows two guiding principles: Implementing robust automation solutions that are easy and affordable for organisations to maintain. Realising process efficiency rapidly by reducing project overheads and time-to-value.

- Hybrid manufacturing is a combination of additive manufacturing (AM) and subtractive manufacturing within the same machine.

- Additive Manufacturing (AM):

- Additive manufacturing is the process of creating an object by building it one layer at a time. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final product is complete.

- Operators across a variety of different manufacturing industries utilize additive manufacturing in various ways. For instance: Medical device manufacturers use 3D printing to develop high variance products such as dental implants.

- The term “additive manufacturing” refers to the creation of objects by “adding” material. Therefore, 3D printing is a form of additive manufacturing. When an object is created by adding material — as opposed to removing material — it’s considered additive manufacturing.

- Smart Manufacturing (SM):

- Technology-driven approach that utilizes Internet-connected machinery to monitor the production process. The goal of SM is to identify opportunities for automating operations and use data analytics to improve manufacturing performance.

- An example of what the cloud can do for smart manufacturing is the Volkswagen Industrial Cloud, which combines all data from 122 Volkswagen Group facilities and processes it in real time to make improvements.