Siemens – Siemens introduces one of the world’s most innovative circuit protection devices

- Ultra-fast, multifunctional, parametrizable, and sustainable

- Up to 1,000 times faster, plus wear-free switching

- Multiple functions in one device; each can be adjusted individually

- Up to 80 percent less space required in distribution board, compared to conventional solutions

Siemens has developed one of the world’s most innovative circuit protection devices with cutting-edge electronic switching technology. SENTRON ECPD (Electronic Circuit Protection Device) electronically switches off circuit faults if errors occur and, if necessary, trips the mechanical isolating contact downstream. Up to now, disconnection was handled purely through electro-mechanical elements.

“This innovation offers a variety of benefits and has the potential to revolutionize today’s circuit protection world,” said Andreas Matthé, CEO of Electrical Products at Siemens Smart Infrastructure.

SENTRON ECPD enables completely new approaches in electrical planning, maximizing safety, flexibility and delivering enormous space and energy savings compared to conventional solutions.

“For the first time in the history of circuit protection, it is possible to benefit from several functionalities in one product and to activate them as required by the individual application or adapt them if needed. All of this combined with the solid-state switching technology enables up to a thousand times faster, wear-free switching,” added Matthé.

Ultra-fast

Circuit protection devices are central components of every electrical installation. If certain load current limits are exceeded, these devices disconnect the individual loads to protect people and systems from damage. In the event of a short circuit, for example, this type of disconnection occurs in commercially available circuit breakers in two to three milliseconds.

In comparison, SENTRON ECPD disconnects up to a thousand times faster, minimizing the occurring short-circuit energy. This ensures maximum safety for people, systems, and electrical equipment. SENTRON ECPD also offers wear-free switching, which increases the service life of systems and reduces maintenance and repair costs. In addition, the integrated cyclical self-test (including the integrated RCD function) raises safety to an entirely new level not covered by current concepts.

Multifunctional and parametrizable

The smart SENTRON ECPD offers more functionalities in one compact design, saving space and costs. The range of functions can be customized as required. New functions can be easily activated on the SENTRON ECPD without having to purchase a new device and functionally adapt it into the circuit. The SENTRON powerconfig app makes this task easy and convenient.

SENTRON ECPD can be adjusted as required and adapts perfectly to the requirements of the application, for example with regard to rated current, tripping limits or behavior. These properties offer major planning and cost advantages. For example, circuits can simply be designed based on the rated current of the loads instead of the significantly higher inrush current peaks that occur briefly with certain load types, such as LED lights. This reduces complexity as well as planning and installation efforts and saves on materials such as copper.

Reducing operating costs and downtime

SENTRON ECPD offers full transparency on energy consumption in the final circuit through radio-based communication with the SENTRON Powercenter 1000 and 3000 gateways. This enables measures to optimize systems and processes, for example as part of energy management in accordance with ISO 50001, which in turn allows for efficient reductions in energy and operating costs.

For the first time, it is possible to perform detailed condition monitoring of the applications at the final circuit level. This substantially increases availability and operational reliability. The large volume of measurement data enables the detection of irregularities and deviations and creates a reliable planning basis for preventive maintenance. SENTRON ECPD can be easily integrated into higher-level systems by using the open Modbus TCP standard.

SENTRON ECPD makes it possible to carry out remote diagnostics and remote switching during normal operation as well as in the event of a fault. This offers significant benefits, especially for remote applications without direct on-site support. In addition, it is easier to localize and identify faults by differentiating the cause of the fault.

Sustainable

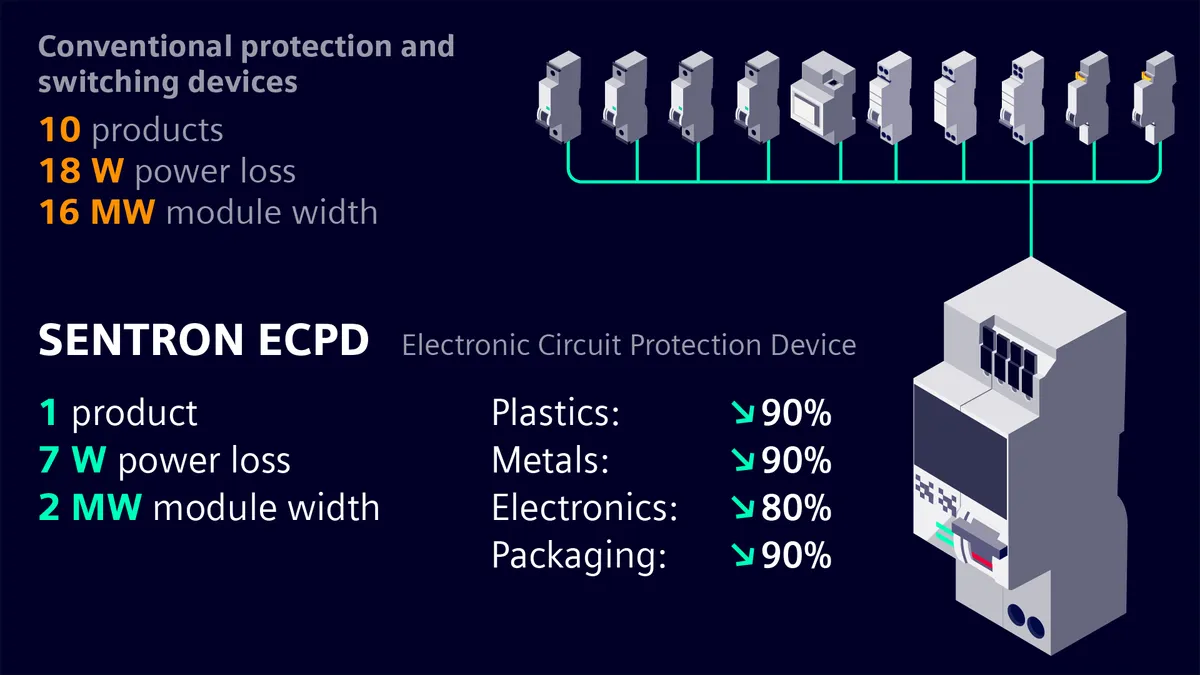

SENTRON ECPD combines multiple product functions in one device. Depending on the application, this allows savings of up to 80 percent on electronics, 90 percent on metals and 90 percent on plastics. Overall, SENTRON ECPD is approximately 90 percent lighter than the devices otherwise required. Compared to solutions based on today’s conventional technology, SENTRON ECPD also requires up to 80 percent less space in the distribution board, eliminating the need for costly structural measures.

For further information on the ECPD, please see www.siemens.com/sentron-ecpd

SourceSiemens

EMR Analysis

More information on Siemens: See full profile on EMR Executive Services

More information on Dr. Roland Busch (President and Chief Executive Officer, Siemens AG): See full profile on EMR Executive Services

More information on Siemens Smart Infrastructure: https://new.siemens.com/global/en/company/about/businesses/smart-infrastructure.html + Smart Infrastructure is shaping the market for intelligent, adaptive infrastructure for today and the future. It addresses the pressing challenges of urbanization and climate change by connecting energy systems, buildings, and industries. SI provides customers with a comprehensive end-to-end portfolio from a single source – with products, systems, solutions, and services from the point of power generation all the way to consumption. With an increasingly digitalized ecosystem, it helps customers thrive and communities progress while contributing toward protecting the planet. Siemens Smart Infrastructure has its global headquarters in Zug, Switzerland. As of September 30, 2023, the business had around 75,000 employees worldwide

More information on Matthias Rebellius (Member of the Managing Board and Chief Executive Officer, Siemens Smart Infrastructure, Siemens AG): See the full profile on EMR Executive Services

More information on SENTRON ECPD by Siemens: https://www.siemens.com/global/en/products/energy/low-voltage/components/sentron-protection-devices/sentron-ecpd.html + The SENTRON ECPD (electronic circuit protection device) is one of the first of its kind in the world with electronic switching. Its impressive features include ultra-fast switching, flexible parameterization, and a wide range of functions. The smart device simplifies your electrical planning, helps you save resources, and optimally supports power distribution system operation.

Electromechanical switching is a thing of the past! The SENTRON ECPD is the first device to use series connection of state-of-the-art semiconductor technology with electromechanical components in the main current path. Its smart protection algorithm is significantly faster and more precise in both fault detection and tripping. Numerous add-on functions can be activated and adapted as needed, opening up a world of new possibilities.

More information on Andreas Matthé (Chief Executive Officer, Electrical Products, Siemens Smart Infrastructure, Siemens AG): See the full profile on EMR Executive Services

More information on ISO (International Organization for Standardization): http://www.iso.org/ + ISO is the world’s largest developer of International Standards. Through our members and their stakeholders, we bring people together to create International Standards that respond to global challenges. ISO standards support global trade, drive inclusive and equitable economic growth, advance innovation and promote health and safety to achieve a sustainable future. Follow us to learn more about standards and how you can participate to making lives easier, safer, and better.

EMR Additional Notes:

- Switchgears:

- Broad term that describes a wide variety of switching devices that all fulfill a common need: controlling, protecting, and isolating power systems. This definition can be extended to include devices to regulate and meter a power system, circuit breakers, and similar technology.

- Switchgear contains fuses, switches, and other power conductors. However, circuit breakers are the most common component found in switchgear.

- Performs the function of controlling and metering the flow of electrical power in addiction to acting as interrupting and switching devices that protects the equipment from damage arising out of electrical fluctuations.

- There are three types of switch gears namely LV (Low voltage), MV (Medium voltage) and HV (High voltage) Switchgear.

- Circuit Breakers:

- Mechanical electrical switch designed to protect an electrical circuit from damage caused by overcurrent/overload or short circuit. Its basic function is to interrupt current flow after protective relays detect a fault.

- By definition a circuit breaker is an electrical safety device, a switch that automatically interrupts the current of an overloaded electric circuit, ground faults, or short circuits.

- Fuses:

- Single time mechanical circuit interruption in an over-current situation through fusion of a graded electrical conductor. Employed in 30KV to 100KV range.

- Electrical safety device that operates to provide overcurrent protection of an electrical circuit. Its essential component is a metal wire or strip that melts when too much current flows through it, thereby stopping or interrupting the current.

- ACB (Air Circuit Breakers):

- Uses air as insulating medium.

- Air circuit breaker is a circuit breaker for the purpose of protecting low voltage circuit, mainly for energizing and cutting off high current

- VCB (Vacuum Circuit Breakers):

- Vacuum is used as the means to protect circuit breakers.

- Circuit breaker where the arc quenching takes place in a vacuum medium. The operation of switching on and closing of current carrying contacts and interrelated arc interruption takes place in a vacuum chamber in the breaker which is called a vacuum interrupter.

- AIS (Air Insulated Switchgears):

- Air is used for insulation in a metal-clad system

- Secondary power distribution device and medium voltage switchgear that helps redistribute the power of a primary power distributor powered by a high voltage distribution transformer. AIS controls, protects and isolates electrical equipment in power transmission and distribution systems.

- GIS (Gas Insulated Switchgears):

- All working components assembled under SF6 (Sulfur Hexafluoride HV Switchgears) gas-tight casing.

- Compact metal encapsulated switchgear consisting of high-voltage components such as circuit-breakers and disconnectors, which can be safely operated in confined spaces.

- OCB (Oil Circuit Breakers):

- Vapors a portion of oil to blast a jet of oil through the arc.

- Circuit breaker which uses insulating oil as an arc quenching medium

- Hybrid Circuit Breakers:

- Combines Air-insulated and SF6 Gas-insulated technologies.

- MCB (Miniature Circuit Breakers):

- Employed in domestic households to safeguard against overload. Rated current max. 100 A.

- Electrical switch that automatically switches off the electrical circuit during an abnormal condition of the network means an overload condition as well as a faulty condition. Nowadays we use an MCB in a low-voltage electrical network instead of a fuse.

- Circuit breakers have a tripping relay mechanism, while MCB has a tripping release mechanism. Circuit breakers have a high rupturing capacity, but the MCB has a low rupturing capacity. Circuit breakers are used in High Voltage systems, while MCBs are used in Low Voltage systems.

- RCCB (Residual Current Circuit Breakers):

- To safeguard against electrical shock arising out of indirect contact and includes the detection of residual current such as earth leakage.

- Current sensing device, which can automatically measure and disconnect the circuit whenever a fault occurs in the connected circuit or the current exceeds the rated sensitivity.

- MCCB (Molded Case Circuit Breakers):

- Incorporates insulating material in the form of molded casing within circuit breaker. Rated current up to 2,500 A.

- MCCB has a higher interrupting capacity, meaning it can handle larger loads than a conventional breaker. Generally, a standard breaker is used for residential and light commercial applications, while an MCCB is suitable for industrial and heavy commercial applications.

- Disconnectors:

- Automatic switching device that offers specific isolating distance on the basis of specific requirements.

- Disconnectors (also known as Isolators) are devices which are generally operated off-load to provide isolation of main plant items for maintenance, or to isolate faulted equipment from other live equipment.

- Contactors:

- Works alike high-current switching systems but at higher voltage rates. Contactors can however not be utilized as disconnecting switches. Contactors are employed in 30KV to 100KV range.

- Special type of relay used for switching an electrical circuit on or off.

- Electrical device that is widely used for switching circuits on and off. As such, electrical contactors form a subcategory of electromagnetic switches known as relays. A relay is an electrically operated switching device that uses an electromagnetic coil to open and close a set of contacts.

- PTCB eFuse Circuit Breaker:

- Electronic micro fuse for DIN rail protecting electronically nominal currents below 1A to facilitate the clear detection of faults and supports precise fault localization and fast recovery. Response times are shorter compared to conventional fuse protection and the exact current value can be adjusted at any time

- RCD (Residual Current Devices):

- Sensitive safety device that switches off the electricity within 10 to 50 milliseconds if there is an electrical fault. An RCD is is designed to protect against the risks of electrocution and fire caused by earth faults.

- The difference between a circuit breaker and an RCD switch is the purpose of a circuit breaker is to protect the electrical systems and wiring in a home while the purpose of an RCD switch is to protect people from electrocution.

- RCBO (Residual Current Breaker with Over-Current):

- RCDs can protect against electric shocks, residual currents, and earth faults. On the other hand, RCBOs can do what RCDs can do and protect a circuit from short circuits and overload. RCBOs are essentially a combination of MCB and RCCB.

- An RCBO protects electrical equipment from two types of faults; residual current and over current. Residual current, or Earth leakage as it can sometimes be referred to, is when there is a break in the circuit that could be caused by faulty electrical wiring or if the wire is accidentally cut.

- Ring Main Unit (RMU):

- Medium voltage, gas-insulated, fully sealed cabinet used to measure, connect, and integrate transformer protection functions with a fixed type breaker. Ring Main Units are safe, reliable, low-maintenance, and easy to replace switchgear.

- A ring main unit (RMU) is a factory assembled, metal enclosed set of switchgear used at the load connection points of a ring-type distribution network.

- Load Center – Panel Board – Switch Board:

- A load center is used in residential and light commercial applications to distribute electricity supplied by the utility company throughout the home or building to feed all the branch circuits. Each branch circuit is protected by the circuit breaker housed in the load center. In the event of a short circuit or an overload on a branch circuit, the circuit breaker will cut the power before any potential property damage or personal injury can occur.

- A load center provides similar functionality in a power distribution system as a switchboard and a panelboard. As far as UL and the NEC standards are concerned, there is no difference between a panelboard and a load center.

- However, Panelboards are typically deeper than load centers and can accommodate both bolt-on circuit breakers as well as plug-in breakers, whereas a load center is limited to plug-in breakers.

- Switchboards are often the typical choice for industrial establishments. These panelboards generally house circuit breakers that can manage and supply electricity for machines with high-voltage demands.

- Panelboards are only accessible from the front (as mentioned above), but switchboards allow rear access as well.

- Solid-State Circuit Breakers:

- Solid-state device, electronic device in which electricity flows through solid semiconductor crystals (silicon, gallium arsenide, germanium) rather than through vacuum tubes.

- The solid-state breaker concept replaces the traditional moving parts of an electromechanical circuit breaker with semiconductors and advanced software algorithms that control the power and can interrupt extreme currents faster than ever before.

- LED:

- LED stands for light emitting diode. LED lighting products produce light up to 90% more efficiently than incandescent light bulbs. How do they work? An electrical current passes through a microchip, which illuminates the tiny light sources we call LEDs and the result is visible light.

- A light-emitting diode is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons.

- LED vs. Halogen:

- Halogen bulbs, while lasting longer than incandescent bulbs, only last up to 2,000 hours. In contrast, LED bulbs can last up to 25,000 hours, and LED tubes are rated for up to 50,000 hours. LED bulbs can use as much as 80% percent less energy than halogen bulbs.

- There’s obviously a clear winner when it comes to LED vs halogen lighting. LED lights are more energy-efficient, have a longer lifespan, and offer more choices in color temperature. They do cost a little more, but their extremely long lifespan easily offsets the higher upfront cost.

- microLED:

- Compared to widespread LCD technology, microLED displays offer better contrast, response times, and energy efficiency. They are also capable of high speed modulation, and have been proposed for chip-to-chip interconnect applications.

- MicroLED prototype displays have been shown to offer up to 10 times more brightness than the best OLED panel while being significantly more power efficient, making them an exciting new technology in the world of displays.

- OLED (Organic Light-Emitting Diode):

- This refers to the panel that’s used inside an OLED TV – or any other kind of OLED screen. So it’s the OLED panel makes OLED TVs stand out in comparison to other types of panels. You’ll also find CRT (cathode ray tube), LED (light-emitting diode), LCD (liquid crystal display), or QLED (quantum dot).

- LED LCD screens use a backlight to illuminate their pixels, while OLED’s pixels produce their own light. You might hear OLED’s pixels called ‘self-emissive’, while LCD tech is ‘transmissive’. The light of an OLED display can be controlled on a pixel-by-pixel basis.

- OLED TVs should offer better overall eye comfort than QLED and any other LCD-based screen, because OLED produces significantly less blue light than LED-backlit QLED TVs.

- Modbus Protocol:

- Modbus is a data communication protocol that is based on a request-response model. Previously referred to as a master-slave protocol, the Modbus organization replaced the terms master and slave with server and client in 2020.

- Modbus is used for transmitting information between devices that are connected to buses or networks over serial lines or Ethernet and, increasingly, using wireless.

- Modbus is the most widely used network protocol in the industrial manufacturing sector. The most common use case is the communication between a human-machine interface (HMI) or supervisory control and data acquisition (SCADA) system and a sensor, programmable logic controller (PLC), or programmable automation controller (PAC). It provides a hardware-agnostic, cost-effective way to enable the interoperability of disparate automation equipment.

- Modbus is popular because it is open source, simple to use, and used everywhere, making it a reliable solution for transferring discrete or analog I/O and register data between control devices.

- TCP (Transmission Control Protocol):

- TCP is a standard that defines how to establish and maintain a network conversation by which applications can exchange data. TCP works with the Internet Protocol (IP), which defines how computers send packets of data to each other.

- IP Communication:

- The Internet Protocol (IP) is defined as the protocol for sending data from one computer to another across the Internet, with each computer having at least one IP address that identifies it from all other computers on the Internet.

- MoIP, or mobile communications over internet protocol, is the mobilization of peer-to-peer communications including chat and talk using internet protocol via standard mobile communications applications including 3G, 4G, 5G, GPRS, Wi-Fi …

- Voice over Internet Protocol (VoIP), is a technology that allows you to make voice calls using a broadband Internet connection instead of a regular (or analog) phone line.